Beacon Machine Manufacturing Co.,ltd

What is the use of diesel genset injectors? How to check

16.12.2024ID: 19Views:

The structure of the diesel generator set injector is mainly composed of injector nozzles, thimbles, solenoid valves, control pistons and ball valves. So what is its role, and how should it start to check it? Take a look.

1. The role of the injector

Diesel engine injector is mainly for the purpose of fuel injection, is an important part of the fuel system; its working principle is that high-pressure fuel from the inlet pipe into the person, through the oil channel to the injector A cavity. At this time, high-pressure oil also through the throttle hole into the injector B cavity; due to the B cavity and A cavity pressure is the same, so the injector is closed.

2. Injector inspection

First let the diesel generator set idling, respectively, to loosen the cylinder high-pressure oil pipe, so that the injector rotation to stop spraying, while observing the exhaust smoke color, when there are faults in the injector to stop spraying, the exhaust color will be a significant improvement in the diesel generator set speed change is very small or unchanged. If it is normal injectors stop spraying, the exhaust smoke color has no significant change, and the speed dropped significantly. The injector has been damaged, must be based on the diesel generator set model selection and installation of the corresponding new injector, otherwise it will affect the normal work of the diesel generator set.

Injector injection open pressure is by the top bar parts above the regulator spring pressure size to control. The use of the process should regularly check the injection pressure. This pressure is too high or too low will directly affect the performance of the diesel generator set. In order to ensure that the fuel into the injector nozzle clean, in the injector inlet pipe fitting is equipped with a filter core, it and the inlet pipe fitting with a clearance of 0.025 ~ 0.055mm, found that the fuel is not clean or Thi period of use should be cleaned.

1. The role of the injector

Diesel engine injector is mainly for the purpose of fuel injection, is an important part of the fuel system; its working principle is that high-pressure fuel from the inlet pipe into the person, through the oil channel to the injector A cavity. At this time, high-pressure oil also through the throttle hole into the injector B cavity; due to the B cavity and A cavity pressure is the same, so the injector is closed.

2. Injector inspection

First let the diesel generator set idling, respectively, to loosen the cylinder high-pressure oil pipe, so that the injector rotation to stop spraying, while observing the exhaust smoke color, when there are faults in the injector to stop spraying, the exhaust color will be a significant improvement in the diesel generator set speed change is very small or unchanged. If it is normal injectors stop spraying, the exhaust smoke color has no significant change, and the speed dropped significantly. The injector has been damaged, must be based on the diesel generator set model selection and installation of the corresponding new injector, otherwise it will affect the normal work of the diesel generator set.

Injector injection open pressure is by the top bar parts above the regulator spring pressure size to control. The use of the process should regularly check the injection pressure. This pressure is too high or too low will directly affect the performance of the diesel generator set. In order to ensure that the fuel into the injector nozzle clean, in the injector inlet pipe fitting is equipped with a filter core, it and the inlet pipe fitting with a clearance of 0.025 ~ 0.055mm, found that the fuel is not clean or Thi period of use should be cleaned.

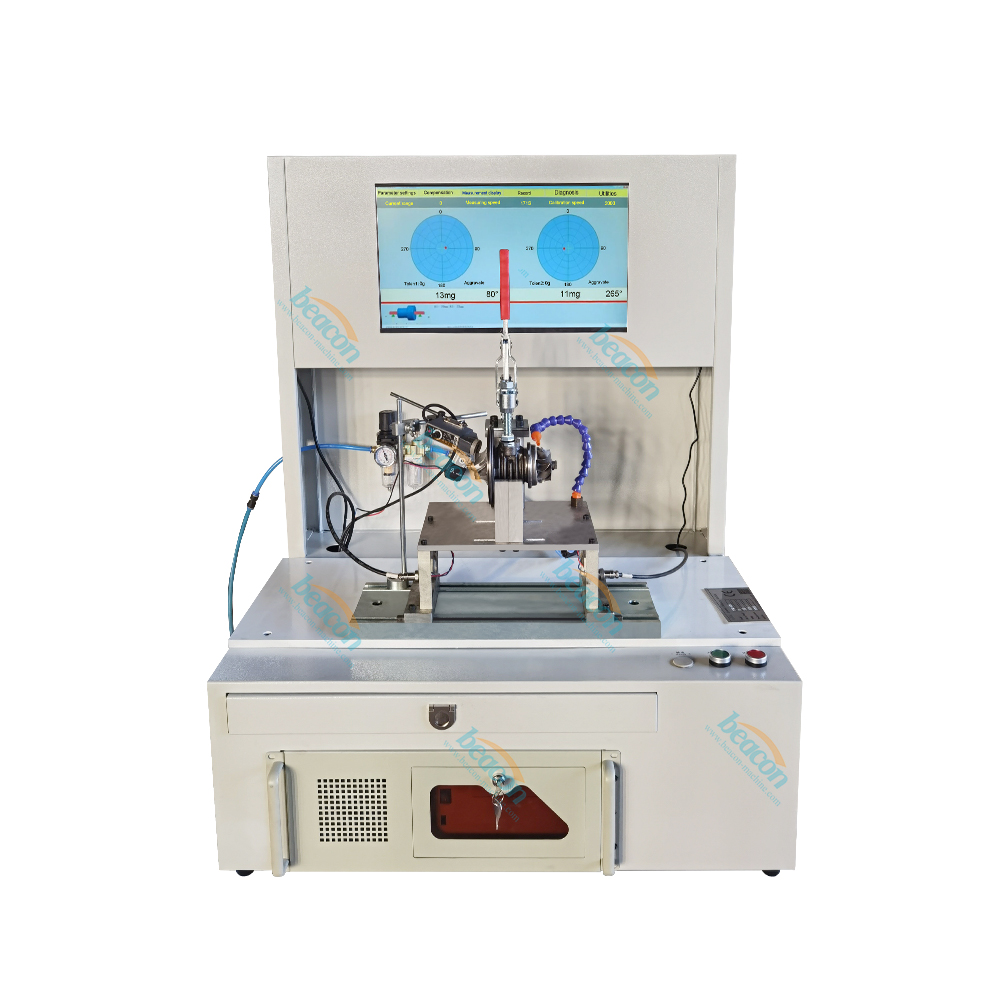

Related products