Beacon Machine Manufacturing Co.,ltd

Beacon Machine Train maintenance electric TR-B hydraulic air brake valve test bench for a train

Beacon Machine Train maintenance electric TR-B hydraulic air brake valve test bench for a train

Introduction

parameter

Train tube constant pressure: 0.5Mpa

Train tube constant pressure: 0.6Mpa

Wind and air pressure: 0.75-0.8Mpa

Balanced total air cylinder air pressure: 0.75-0.8Mpa

Wind and air pressure: 0.5 0.005Mpa

Air cylinder air pressure: 0.6 0.005Mpa

Train pipe air pressure: 0.5 0.005Mpa

Train pipe air pressure: 0.6 0.005Mpa

Working cylinder pressure: 0.5 0.005Mpa

Working cylinder pressure: 0.6 0.005Mpa

Brake cylinder air pressure: 0.5 0.005Mpa

Brake cylinder air pressure: 0.00Mpa

*Test data from Beacon laboratory

product video

Beacon Machine Train maintenance electric TR-B hydraulic air brake valve test bench for a train

Features

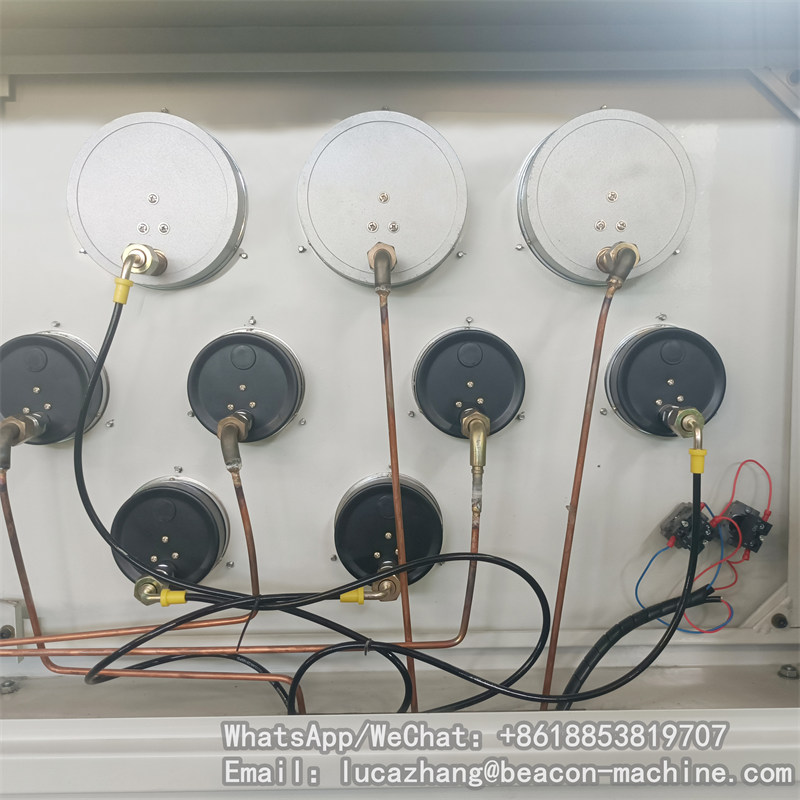

The test bench adopts the full pointer pressure gauge display, which makes the abstract and cumbersome brake test process intuitive and clear, which fundamentally improves the reliability of the test, reduces the labor intensity of operators, and effectively avoids missed inspections during the test. False detection, improve the qualified rate of loading.

Test items

1. All the valve parts of the JZ-7 brake machine can be tested and tested, including: automatic brake valve, separate brake valve, shut-off valve, main valve, auxiliary valve, action valve, and can also be tested for comprehensive performance. .

3. The installation and clamping of each valve part adopts manual clamping.

4. The composition of the test bench: a cold plate design bench, sprayed on the surface, 9 pressure gauges, respectively showing the balance air cylinder, train cylinder, working air cylinder, action cylinder, brake cylinder, action air cylinder, pressure reduction air cylinder , the main air cylinder and the shut-off valve pipe, and is equipped with an independent air source switch key and power switch, which is more convenient for testing and testing.

Product details

Our factory

Our Service

Related products