Beacon Machine Manufacturing Co.,ltd

Our factory

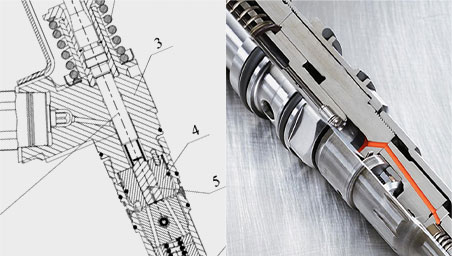

design

Beaconmachine has a R&D team of more than 30 people headed by industry leaders. We worked hard to overcome difficulties, solved the problems in spray technology, and developed injector components with better structure and better reliability. Completed the injector assembly. Hydraulic system design, processing and test verification of oiler assembly. The common rail oil nozzle design and processing technology have achieved breakthroughs and are on par with similar international products. The company pays attention to market demand during the research and development process and is committed to developing products that meet market demand.

Material Selection

Steel requires preliminary processing through casting, drawing and other processes. After cutting and blanking, the shell is rough turned. After the injector shell is cast, surface treatment is performed, such as cutting, grinding, spraying, deburring, grinding, etc., to ensure the beautiful appearance and service life. During this period, it must undergo multiple tempering and quenching processes to meet the original process design requirements of the injector.

CNC

The company all uses CNC processing equipment, which has the following characteristics 1. High precision: CNC machining has very high precision and can be accurate to several microns or even smaller dimensions, ensuring the consistency and precision of processing quality. 2. High efficiency: CNC processing is automatically controlled by computer programs without manual operation, which improves processing efficiency and production speed. 3. Flexibility: CNC machining can be quickly adjusted and modified according to needs. Just modify the computer program without remaking the mold. 4. Automation: CNC processing can realize automated production, reducing the need for manual intervention and operations, reducing labor costs and the probability of human errors.

Assemble

All parts to be assembled must be dried by clean compressed air and then enter the assembly workshop through clean channels. In a workshop using advanced dust-free walls and air evolution, use the assembly adjustment tool set and follow the assembly process to select the appropriate adjustment pad. , adjust the mechanical structure of the injector to the specification requirements.

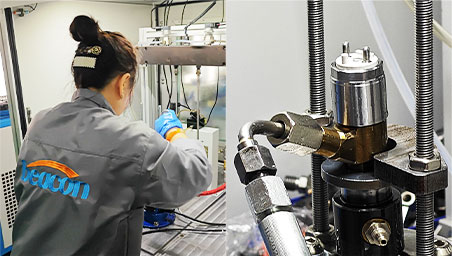

Factory inspection

It undergoes strict inspection before leaving the factory. The test items include: Fuel injector parts performance test, fuel injector parts durability test, fuel injector performance test, fuel injector durability test, fuel injector spray quality test, fuel injector sealing test, fuel injector needle valve opening Pressure test, needle valve slideability test, appearance inspection, general inspection, chemical composition, lift and flow, shape and position tolerance, roughness, metallography and hardness, spray quality, aging treatment, low number of injections, material composition, Flow rate, carburized layer depth, sliding property, surface hardness

Package

Each common rail injector is marked with the following information in a conspicuous position, and the markings are always clear. 1—Manufacturer name (logo) or trademark: ——Product model or code: ——Other content is marked according to the user agreement. Product packaging requirements 1 The common rail injector is equipped with various protective parts (shields, protective caps, etc.) to prevent the inner cavity from being polluted and bumped. .2 When packaging common rail injectors, consider appropriate transportation protection conditions and use sturdy packaging boxes lined with moisture-proof materials to fully protect them. Ensure that the common rail injector is not damaged or affected by moisture. Each packaging box is accompanied by a certificate of conformity signed by the inspector and relevant factory documents.

Delivery

The products shipped from the factory meet the requirements of the order contract. The company name, product name, model, quantity, gross weight, upward symbol, date of shipment from the company, and packaging (anti-rust) effective date are marked on the packaging box. Through the convenient logistics network, the product can be shipped as soon as possible. Delivered to you.