Beacon Machine Manufacturing Co.,ltd

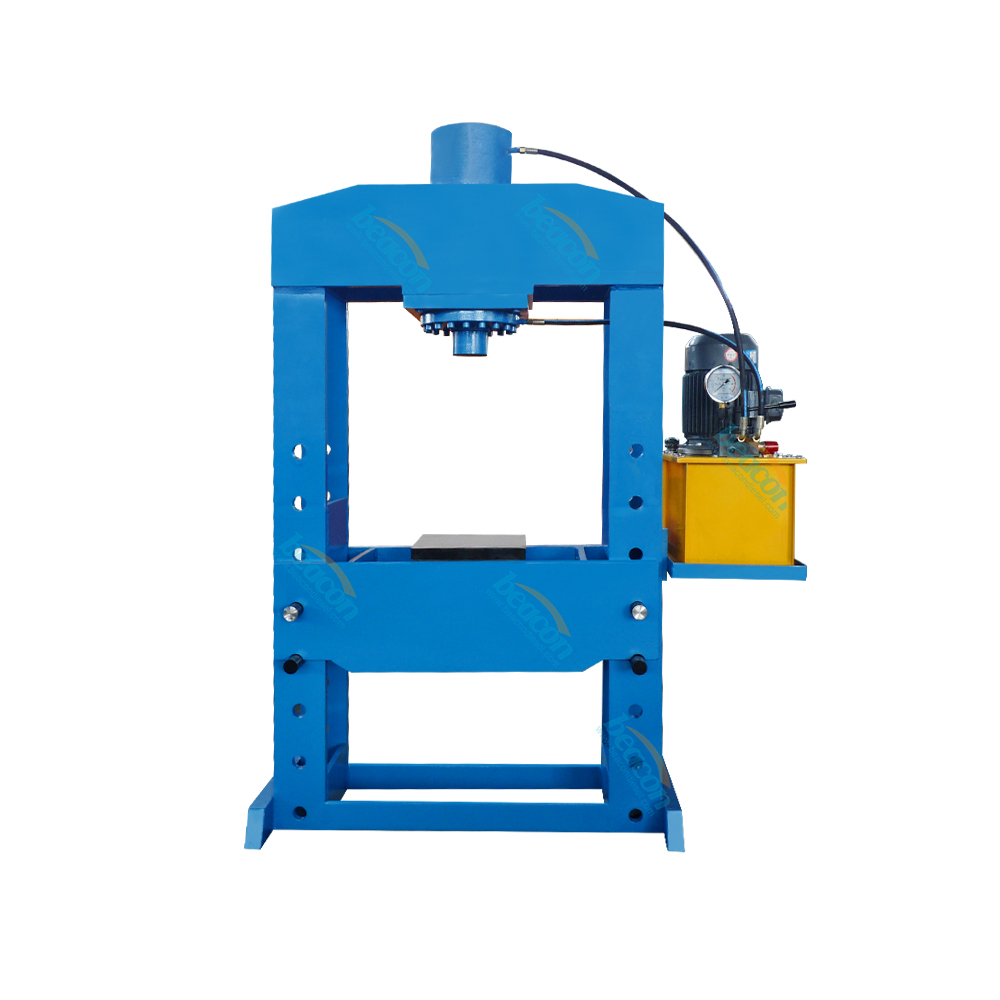

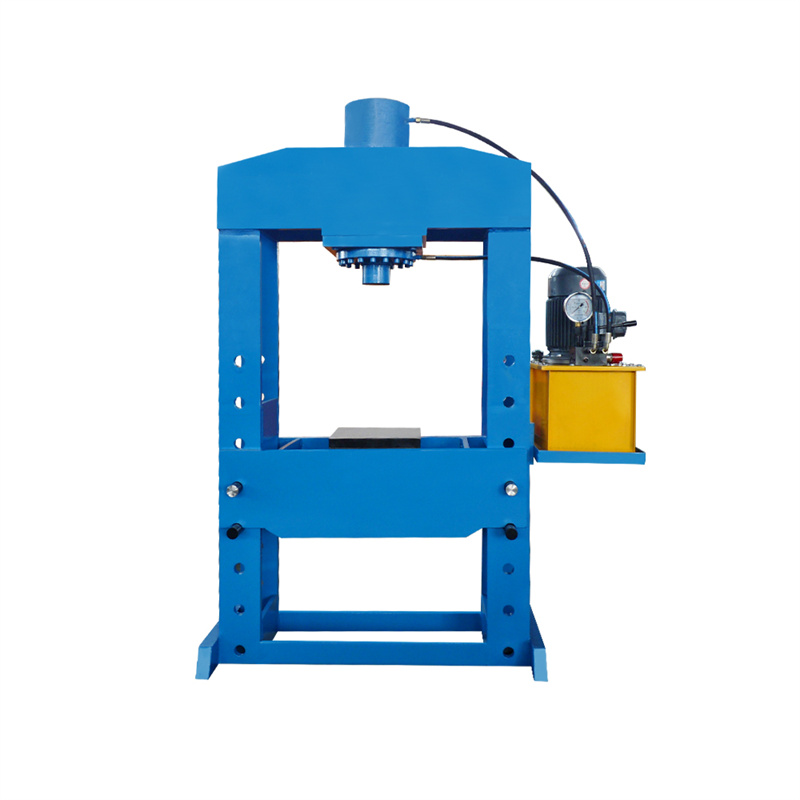

Beacon 20/50/100 Ton electric Hydraulic Press Machine for truck repair workshop

Beacon 20/50/100 Ton electric Hydraulic Press Machine for truck repair workshop

Introduction

parameter

2.When in work , make sure the surface of accessories is level off.

3.The rated power of oil pump has been well adjusted when leaving factory , so no need to regulate more. If problem occurs, such as the hydraulic pressure is not enough , you should check whether the oil in gasoline tank is enough. In some special case, when must need to regulate the adjuster , done only by professionals.

4.Every 3000 hours work time, change the hydraulic oil. Use N20-30in winter, and N46 in summer .

*Test data from Beacon laboratory

product video

Beacon 20/50/100 Ton electric Hydraulic Press Machine for truck repair workshop

This is a kind of compound oil pump. The piston works in high speed in low pressure, and the maximum rated pressure can reach to Mpa in high pressure.

|

|

1. Ignite the engineer at the first time to use it ,and check the running way.

2. No load run the engineer ,exclude the air in the oil jar by using the way of return poison twice within the area of mm up and down.

3. Choose the height of work platform according to the size of pts, and insert two poles of bearing the pressure into the round hole separately.

4. adjust the travel: broadcast to manual mode, make the pressure head contact the workpiece, adjust the side travel adjustment parts to the position required by the travel switch light to lock, and then make the cylinder run to the starting position to adjust the travel adjustment parts to the top travel switch light to lock.It is then played into automatic mode, and the machine runs at the set time

5. Time adjustment: open the distribution box and turn the time controller to the required time

Our factory

Our Service

Related products