Beacon Machine Manufacturing Co.,ltd

Beacon ABML-50CX brake disc automatic correction, balance and deweighting machine

Beacon ABML-50CX brake disc automatic correction, balance and deweighting machine

Introduction

parameter

2. Maximum diameter of balance correction workpiece: Φ500mm

3. Diameter of milling workpiece: Ф200-Φ500mm

4. Workpiece positioning hole diameter: Ф80-Ф250mm

5. The maximum height of the workpiece: 180mm

6. Balance speed: 200-1500rpm (servo control)

7. Main motor power: 3kW (servo motor)

8. The power of milling motor is 2.2kW.

9. The maximum stroke of milling radial feed: 300mm

10. Height adjustment range of milling power head: 0-120mm;

11. Specification of milling power head: BT40

12. Weight-removing method: continuous arc high-speed dry milling with three-sided edge disc milling cutter;

13. Maximum diameter of milling cutter: 120mm

14. Unbalance reduction rate: ≥95%; (standard rotor)

15. Weight-removal efficiency: 3000-6000gcm/min; (when the workpiece has a weight-removal diameter of 470mm);

16. Milling cutter form: machine-clamped carbide disc milling cutter;

17. Maximum milling depth: 12mm

18. Milling width: 8-32mm;

19. The maximum angle of milling: 100°

20. Measuring fixture accuracy: upper and lower cone positioning: ±10um;

21. Repeat accuracy: one-time clamping repeat accuracy ≤10g.cm, repeated clamping accuracy: ≤±50g.cm

22. Phase error of unbalance: ≤±2°

23. Working speed of milling cutter head: 150-500 rpm (frequency conversion speed regulation)

24. Measuring beat: 6S-12S

25. Measurement + milling beat: ≤70S-120S/piece

26. Balance accuracy: 3gmm/kg

*Test data from Beacon laboratory

product video

Beacon ABML-50CX brake disc automatic correction, balance and deweighting machine

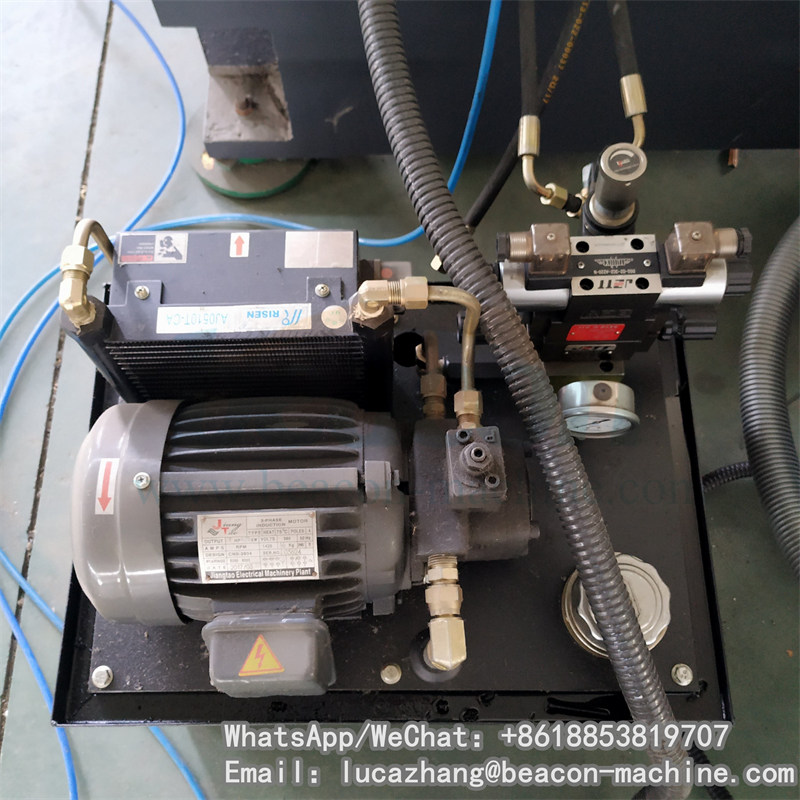

The automatic balancing machine is composed of a balanced rotary spindle part, a rotary table part, a milling power head and an automatic feed part, an electrical control cabinet and a measuring part.

The upper IPC of the measuring part uses a 32-bit industrial computer, a 15-inch touch screen, and UBM101 balance The dedicated measurement software runs under the Windows 7 operating system. The software mainly completes dynamic balance measurement, records storage statistics and prints. The stored data can be downloaded via U disk at any time.

The touch-type 15-inch color screen is used to display the size and position of the imbalance, and is a man-machine interface that automatically controls the operation. It is installed in an operation cabinet with dust-proof protection, and the action of the mechanical part is controlled by the upper computer and the servo driver; Automatic measurement of unbalance, automatic positioning, automatic pneumatic locking of the workpiece, automatic control of the milling machine to the deduplication position, and finally deduplication operation. The machine tool has automatic and manual switching functions. It is very convenient to manually adjust the machine tool. Various feed speeds and return speeds can be set.

The mechanical part adopts the single station structure of the casting base, balance measurement and automatic milling in the same station, the box body is a welding structure, the casting vertical support, the high rigidity milling machine structure, the milling cutter bar can be lengthened, and the milling machine can move forward and backward along the linear guide. In order to facilitate the loading and unloading of the workpiece and the change of size specifications, the up and down adjustment of the milling machine is adjusted by electric, adjusted to the height of the workpiece to be milled, and manually locked (when the workpiece is single, after adjusting to the position once, the lock is fixed, no need to adjust) ; The spindle adopts pneumatic locking and automatic positioning. The overall structure of the equipment is centralized, easy to use and simple to operate, which greatly improves work efficiency.

Product details

Our factory

Our Service

Related products