Beacon Machine Manufacturing Co.,ltd

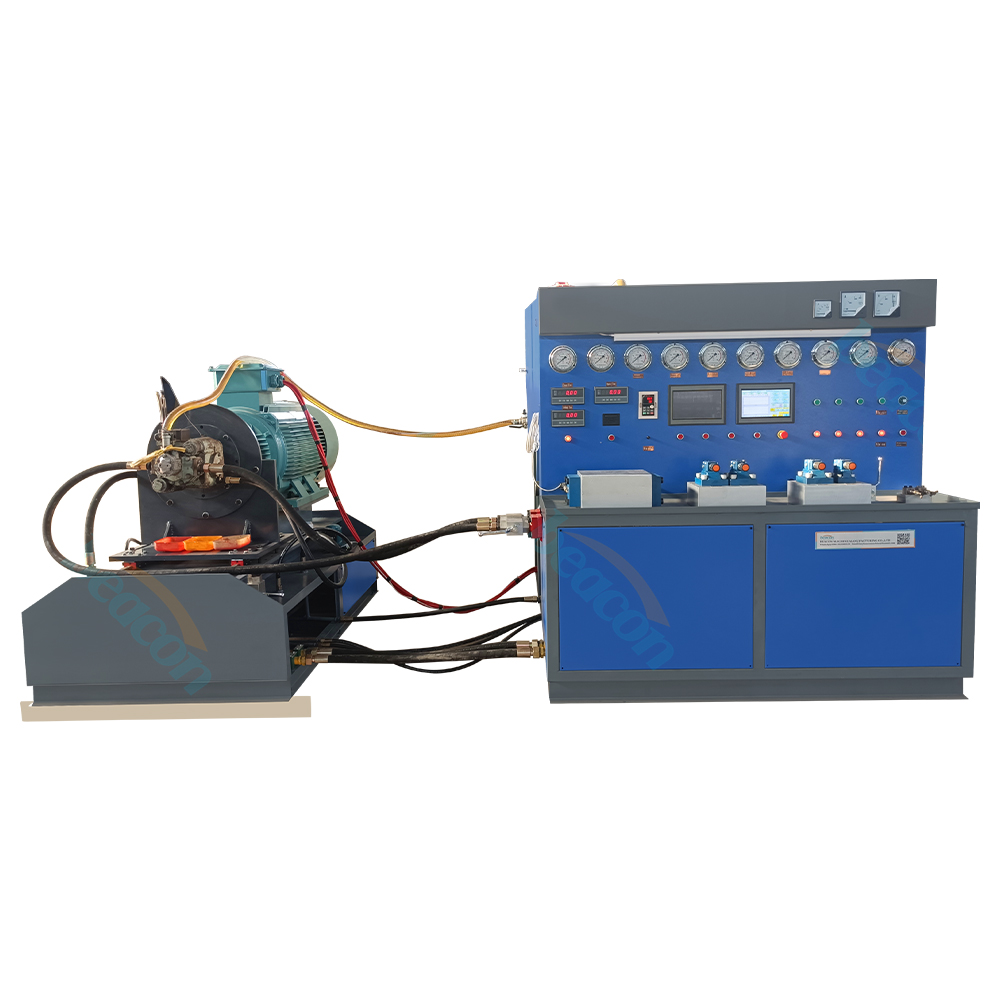

Beacon Machine Auto Repair Tester Equipment HP-B Hydraulic Pump Potor Valve Cylinder Comprehensive Test Bench

Beacon Machine Auto Repair Tester Equipment HP-B Hydraulic Pump Potor Valve Cylinder Comprehensive Test Bench

Introduction

parameter

electric motor: 15 kw

Control cabinet: self made

Flow Sensor: 300+380

relief valve: Beijing Huade

Return oil filter: 10 u

oil suction filter: 100 u

integrated block: self made

Fuel tank and accessory lines: self made

Flow Sensor: 40-2 pieces 15-1 piece

*Test data from Beacon laboratory

product video

Beacon Machine Auto Repair Tester Equipment HP-B Hydraulic Pump Potor Valve Cylinder Comprehensive Test Bench

Test projects:

1. Displacement inspection test: no-load pressure and displacement measurement.

2. Volumetric efficiency test: measure the volumetric efficiency under rated working conditions.

3. Overload test: Maximum displacement, nominal speed, 110% of rated pressure or operation for less than 1 minute at maximum pressure.

4. External leakage: In the above test, check the leakage of the sealing part.

5. The system pressure can reach 35MPa.

Test bench system functions and parameters:

1. Drive mode: motor variable frequency drive, power 75kw+15KW

2. Speed adjustment method: variable frequency speed adjustment 0-3000r/min.

3. Loading method: Manual dual-channel loading 35MPa. Dual pumps can be tested simultaneously.

4. System maximum flow ≦380L/min

5. The maximum flow rate of the auxiliary system is ≦7.5L/min, and the maximum pressure of the auxiliary system is 16.5MPa.

6. Equipment operating environment temperature range: 0-60℃

7. Equipment power requirements: AC380V (315A)

8. Display mode: rotation speed, flow rate, digital tube display, pressure is displayed by a shock-resistant pressure gauge. Oil supply method: self-priming oil supply and forced oil supply.

9. Test components: mainly test open hydraulic pumps and closed pumps. Auxiliary testing of hydraulic valves, hydraulic cylinders, etc.

10. Left-hand pump and right-hand pump; both can be tested

11. Provide an oil filter pump to recover leaked oil.

12. The 4-stage filtration of the inlet and return oil filter has an alarm function.

13. Fuel tank volume: 1 cubic meter

14. The seller is not responsible for the on-site installation and debugging of the equipment.

15. The main color of the equipment is: orange

16. Pilot oil supply motor power 3KW

17. There are 8 pressure gauges

18. Hydraulic pump, hydraulic motor bench

Product details

Our Service

Our factory

Our Service

Related products