Beacon Machine Manufacturing Co.,ltd

Beacon Machine Auto Repair Tools Diesel Injector Test Bench Common Rail Testing Machine CR777 For Testing CR Injectors

CR777 Diesel Test Bench Common Rail Piezo Injector Calibration Machine

Introduction

parameter

Temperature (non operating) ************** -20~70 ℃ (-4~158 ° F)

Relative humidity (during operation) **** 15% to 95% at 40 ℃ (without frost)

Relative humidity (non operating) ******* 90% at 65 ℃ (no frost)

Host nominal power (KW): 4

Heating pipe power (KW): 1

Overall size (MM): 900x680x1520;

Weight (kg): 220kg

*Test data from Beacon laboratory

product video

Beacon Machine Auto Repair Tools Diesel Injector Test Bench Common Rail Testing Machine CR777 For Testing CR Injectors

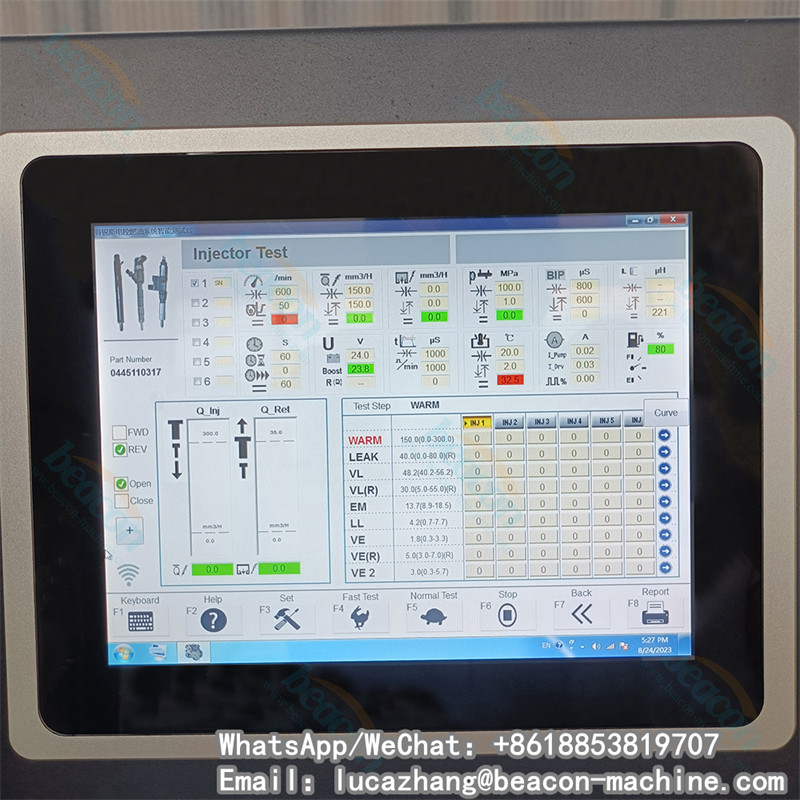

The function of the CR777 co -rail injection device detection table is to imitate the working conditions of the diesel engine ECU (Engine Control Unit). The rail sprayer is done; the driver signal parameter user can set it according to their actual situation and save it to facilitate maintenance personnel to judge and repair the working status of the high -voltage common rail system.

Function Introduction

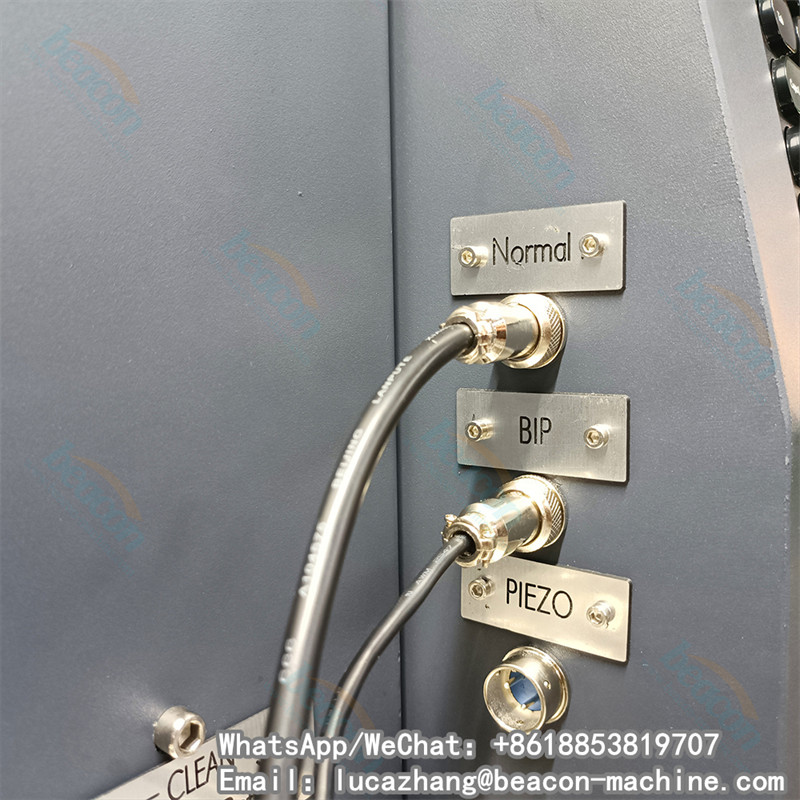

(1)Test Bosch, Delphi, Denso, Siemens, Caterpillar, Cummins, solenoid or piezo common rail injector and pump (Included the pump with 2 ZME metering units).

(2)Injector coding can be generated, including Bosch IQA / IMA / ISA, Denso 16/22/24/26/28/30/32QR, Delphi I2C / I3C, Siemens IIC and Cummins XPI(optional);

(3)Can test Bosch, Caterpillar, Cummins, Delphi EUI and EUP, including Delphi E3 double solenoid EUI and Cummins M11 double pulsing EUI (optional);

(4)Test HEUI injector and HEU pump (optional);

(5)Test Caterpillar 320D pump (optional);

(6)Test VP37,VP44,RED4,Denso V3/V4/V5 pump (optional);

(7)Test Cummins HPI injector,PT pump (optional);

(8)Test Injector response time,EUI/EUP BIP;

(9)Test injector resistance and indctance.

(10)Test the armature lift of the injector solenoid valve (AHE) (optional).

(11)The test plan is consistent with the original data, and the test accuracy reaches the original factory standard;

(12)The database is fully openthe part number can be increased.

(13)Automatic network upgrade, test data and functions are kept up to date

Product details

Our Service

Our factory

Our Service

Related products