Beacon Machine Manufacturing Co.,ltd

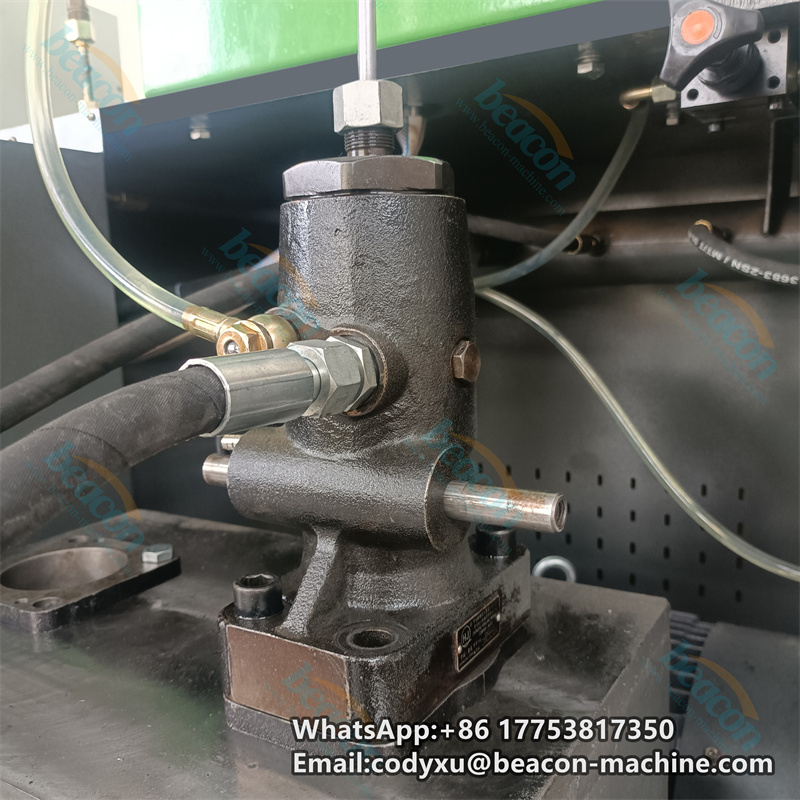

Beacon SPF-A Diesel Fuel Single Cylinder Pump Test Bench Marine Engine Injection Pump Calibration Machine

Beacon SPF-A Diesel Fuel Single Cylinder Pump Test Bench Marine Engine Injection Pump Calibration Machine suitable for the performance test of the internal combustion locomotive diesel jet pump.

Introduction

Main functions:

The SPF-A monomer pump testing table is suitable for the performance test of the internal combustion locomotive 240 diesel jet pump.

The structure of the test table

(1) This product is formed by steel plates. The overall structure is compact and the shape is reasonable.

(2) The shell is sprayed with high -voltage static electricity, which has the characteristics of resistance and wear resistance and a beautiful shell.

(3) The integration of pumps and fuel tanks reduces noise.

(4) The test table is equipped with test fuel tanks, inverters, motors, belt

wheels, camsculators

(5) The front surface of the test table is equipped with a power control switch, which is the power distribution system after opening.

(6) The operating part of the test table is controlled with a digital table.

Main features:

1.The test table has the advantages of reasonable structural, advanced design, good design, good human -machine interface, simple operation, fast and accurate testing, stable and reliable, convenient maintenance, high safety, energy saving and environmental protection, long service life.

2.The test table fuel injection pressure uses a 1.1kW motor to drive 16L oil pump to supply fuel to the fuel injection pump. Control the oil pump-level inverter and the main motor speed through digital instruments to make the fuel injection.

3.Test oil is controlled by constant temperature to eliminate the problem of high differences in data data when temperature changes. All detection data touch control screen display, the final test parameters can be saved, simple operation, and convenient maintenance. Using high -precision pressure sensors, the pressure indicator device is stable and reliable.

The SPF-A monomer pump testing table is suitable for the performance test of the internal combustion locomotive 240 diesel jet pump.

The structure of the test table

(1) This product is formed by steel plates. The overall structure is compact and the shape is reasonable.

(2) The shell is sprayed with high -voltage static electricity, which has the characteristics of resistance and wear resistance and a beautiful shell.

(3) The integration of pumps and fuel tanks reduces noise.

(4) The test table is equipped with test fuel tanks, inverters, motors, belt

wheels, camsculators

(5) The front surface of the test table is equipped with a power control switch, which is the power distribution system after opening.

(6) The operating part of the test table is controlled with a digital table.

Main features:

1.The test table has the advantages of reasonable structural, advanced design, good design, good human -machine interface, simple operation, fast and accurate testing, stable and reliable, convenient maintenance, high safety, energy saving and environmental protection, long service life.

2.The test table fuel injection pressure uses a 1.1kW motor to drive 16L oil pump to supply fuel to the fuel injection pump. Control the oil pump-level inverter and the main motor speed through digital instruments to make the fuel injection.

3.Test oil is controlled by constant temperature to eliminate the problem of high differences in data data when temperature changes. All detection data touch control screen display, the final test parameters can be saved, simple operation, and convenient maintenance. Using high -precision pressure sensors, the pressure indicator device is stable and reliable.

4.The test bench control system can automatically monitor the work of electrical equipment. The power cord is fixed with the device with a galvanized pipe with a galvanized pipe. An accident can be stopped automatically.

parameter

Power: AC380V ± 10 % 50Hz 50Hz

Main motor: 22KW

Oil pump motor: 1.1kW

Fuel fuel tank volume: 34L

Testing table Shape Size: 1600 × 1000 × 1700mm

*Test data from Beacon laboratory

Main motor: 22KW

Oil pump motor: 1.1kW

Fuel fuel tank volume: 34L

Testing table Shape Size: 1600 × 1000 × 1700mm

*Test data from Beacon laboratory