Beacon Machine Manufacturing Co.,ltd

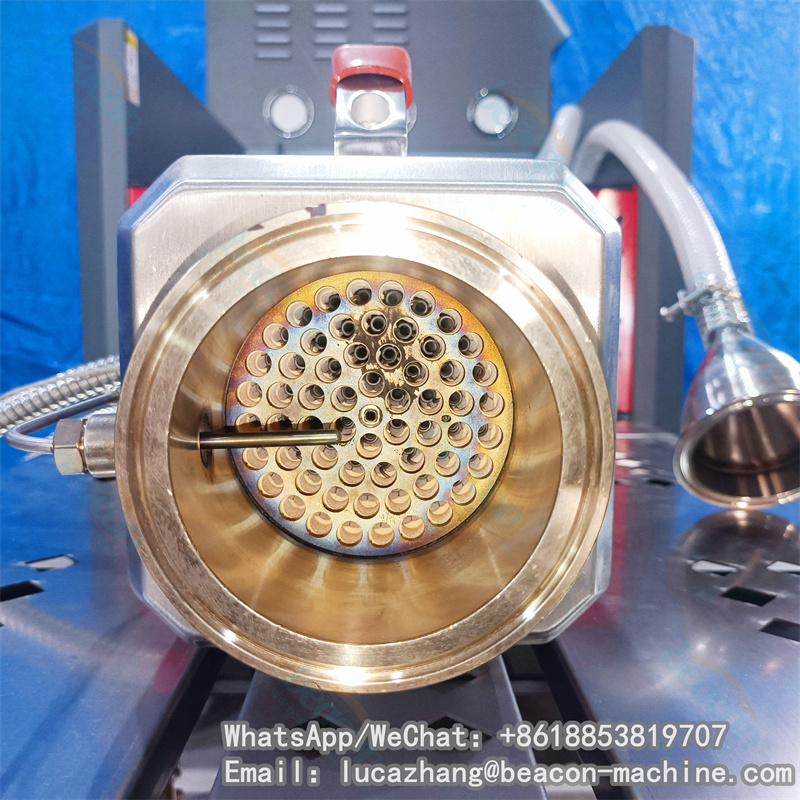

DPF Cleaner Cleaning Machine Diesel Particulate Filter Machine DPF-CL Cutting free High temperature cleaning regeneration

DPF Cleaner Cleaning Machine Diesel Particulate Filter Machine DPF-CL Cutting free High temperature cleaning regeneration

Introduction

parameter

Maximum wind pressure: 23KPa

Host size: 1600*800*1420(mm)

Mobile workbench size: 860*600*380(mm)

Thermal mutual resistance warm water cooler: 830*600*800(mm)

Water storage capacity: 40L

Operating temperature; 0-800 degrees

Total size of equipment: 3200*800*1420(mm)

Gas tank pressure resistance: 1.25MPA (12.5kg)

Power: 0.6KW

*Test data from Beacon laboratory

product video

1. Cutting-free - (various types of DOC, DPF, and SCR do not need to be decomposed to achieve lossless high-temperature regeneration; disassembled DPF can be quickly regenerated through special fixtures; some models can be regenerated directly on the vehicle)

2. No pollution - (coupled with a heat-resistant water cooler to cool down and collect the exhaust heat and carbon ash)

3. Short time-(regeneration is heated directly from the core, without passing through the insulation layer from outside to inside. The total time is shortened from the original 5-10 hours to 40 minutes. After regeneration is completed, the cooling mode is automatically turned on. The cooling time Reduced from the original 2 hours to 5 minutes)

4. Full functions - (The equipment has its own back pressure detection function and is equipped with a data printer. The back pressure of the exhaust pipe can be detected before and after regeneration. After the detection is completed, the back pressure data will be automatically printed. The real-time back pressure can be seen throughout the regeneration process. Regeneration After completion, the temperature and time data will be automatically printed and a test report will be generated)

5. Good effect - (the regeneration process automatically turns on the high-temperature and high-pressure purge mode, and the carbon deposits are not retained. After the high-temperature regeneration is completed, the carbon deposits are completely discharged through the blast mode!)

Product details

Our factory

Our Service

Related products