Beacon Machine Manufacturing Co.,ltd

DPF Cleaning Machine DPF-RGB Regeneration Equipment With Post-Processing And Purge Dust Collection Function Test Bench

DPF Cleaning Machine DPF-RGB Regeneration Equipment With Post-Processing And Purge Dust Collection Function Test Bench

Introduction

parameter

2. Furnace size: 80 * 90 * 100cm

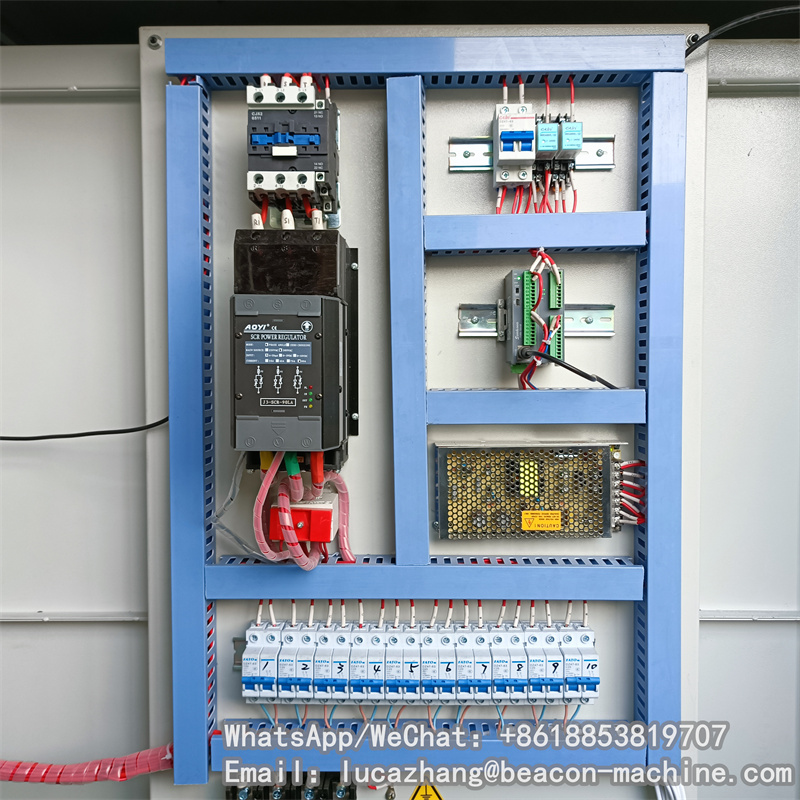

3. Input power supply: AC380V, 50Hz

4. Heating power: 20kw

5. Weight: 750KG

*Test data from Beacon laboratory

product video

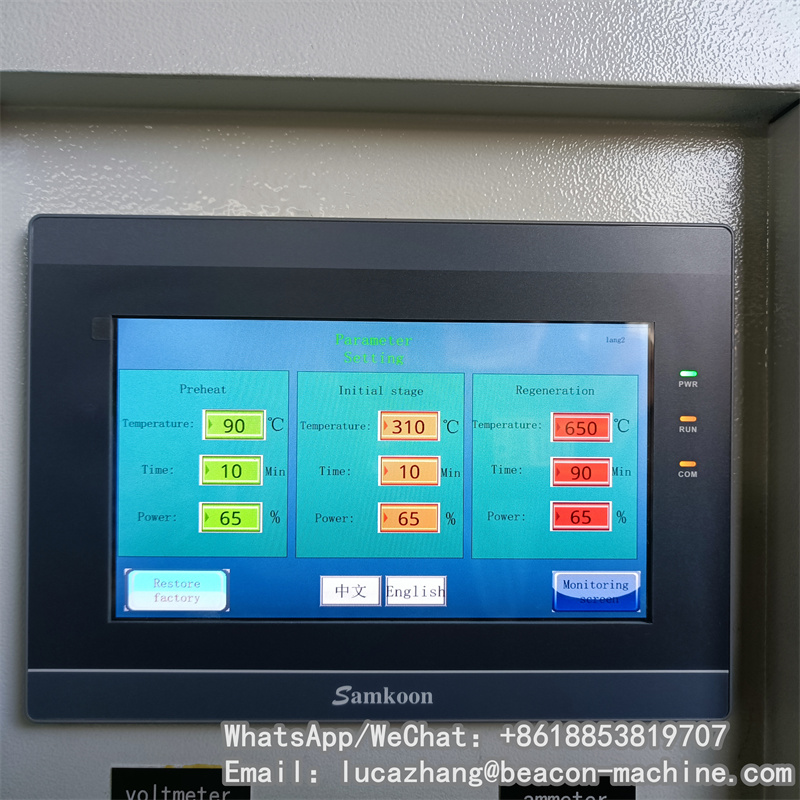

The realization of DPF's function in the whole vehicle mainly has two parts, namely the capture of carbon particles and the reaction treatment of carbon particles. DPF generally adopts a wall-flow filter, which relies on alternately blocking the inlet and outlet of the carrier holes and forcing the airflow through the porous wall to achieve particle capture. The front-stage DOC catalyst oxidizes the NO produced by the combustion in the diesel engine cylinder to produce NO2. After entering the DPF, the NO2 molecular bond can be broken at a relatively low temperature (about 250°C), and the generated oxygen will combust with the captured C particles to form CO2. Most ordinary driving conditions of diesel engine can meet the regeneration temperature (250℃~500℃) in DPF, so PM can be effectively removed. In the particle trap, electric heating is used to generate high temperature, and the trapped particles are burned into CO2 and discharged.

DPF high temperature regeneration equipment has high heating efficiency, fast speed and good effect. It not only saves electricity and energy, but is also easy to maintain and low maintenance costs. Under normal circumstances, the time block from the start of heating to the regeneration temperature. High temperature control accuracy and sensitive response

The use of special scientific insulation layer design and the use of special insulation materials greatly reduce the heat loss caused by heat conduction, thereby greatly reducing energy consumption; a relatively closed regeneration environment can effectively reduce thermal radiation pollution, and then Protect the ecological environment and the health of operators.

Product details

Our factory

Our Service

Related products