Beacon Machine Manufacturing Co.,ltd

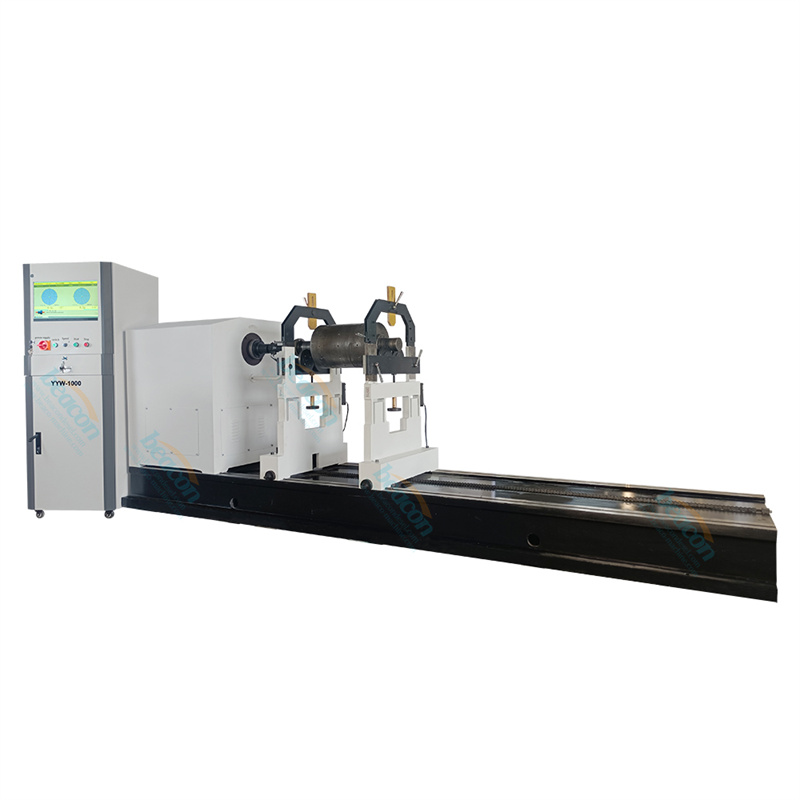

YYW-6000A Cardan Shaft Drive Dynamic Balancing Machine for Truck Drive Shaft Dynamic Balance Testing

YYW-6000A Cardan Shaft Drive Dynamic Balancing Machine for Truck Drive Shaft Dynamic Balance Testing

Introduction

YYW-6000A r is universal coupling and ring belt double drive universal hard bearing horizontal double-sided dynamic balancing machine, equipment models covering the measurement range from a few kilograms to more than 50 tonnes, using roller support, the product is in strict accordance with the G B / T 4 2 0 1- 2006 organisation of production. Equipment measurement by the industrial control computer for data processing, 19-inch LCD screen display real-time display, software GB-2000 universal microcomputer balance measurement system, the measurement system running on the Windows platform with fully automatic programme-controlled amplification module, can achieve the real parameters of any input, any calibration, any angle of the fixture compensation, self-checking, the amount of qualified prompts, the amount of residual imbalance g (grams) and Unequilibrium moment g.cm (g * cm), g.mm (g * mm) a variety of display modes, automatic storage of measurement results and other functions; all Chinese menu structure, calibration and compensation of the operating steps automatically prompted to make the operation simple, easy to use. Strong generality of the equipment is suitable for regular or irregular, smooth or non-smooth surface of the parts of all kinds of parts for dynamic balancing measurements, widely used in electric motors, blowers, diesel engines, agricultural machinery, textile machinery and other industries, can be in a single-sided, double-sided and multiple calibration surface balance measurements, suitable for shafts, discs and the centre of gravity of the outward-facing rotor. It has the advantages of high efficiency, accurate precision, intuitive display and reliable quality.

parameter

Equipment Model YYW-6000A

Maximum mass of work-piece kg 6000

Minimum mass of work-piece kg 400

Maximum diameter of work-piece on bed guideway surface mm φ3000

Minimum distance between two supports mm 400

Maximum distance between two supports mm 2300

Bed length mm 4000*1100*260

pendulum structure Modular construction, roller H-type support

Support shaft diameter mm φ50-250,φ250-450

Balance speed r/min 253/435/708/1140Four-speed mechanical transmission

Minimum Residual Unevenness Measure ≤0.5gmm/kg

reduction in imbalance% ≥95%

Motor power 55KW

Speed control method Frequency control + 4-speed mechanical gears

transmission method Universal joints (two sets for 300nm and 2500nm)

Overall size (L*W*H) 4200*1100*2300

*Test data from Beacon laboratory

Maximum mass of work-piece kg 6000

Minimum mass of work-piece kg 400

Maximum diameter of work-piece on bed guideway surface mm φ3000

Minimum distance between two supports mm 400

Maximum distance between two supports mm 2300

Bed length mm 4000*1100*260

pendulum structure Modular construction, roller H-type support

Support shaft diameter mm φ50-250,φ250-450

Balance speed r/min 253/435/708/1140Four-speed mechanical transmission

Minimum Residual Unevenness Measure ≤0.5gmm/kg

reduction in imbalance% ≥95%

Motor power 55KW

Speed control method Frequency control + 4-speed mechanical gears

transmission method Universal joints (two sets for 300nm and 2500nm)

Overall size (L*W*H) 4200*1100*2300

*Test data from Beacon laboratory

Our factory

Our Service