Beacon Machine Manufacturing Co.,ltd

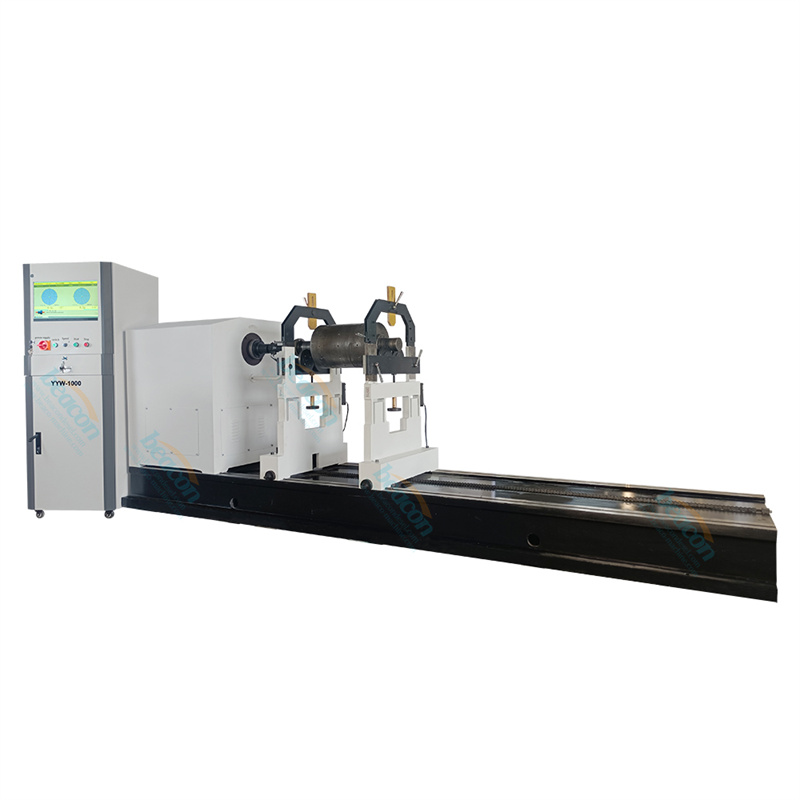

Armature Rotor Balancing Machine YYQ-200S Crank Shaft Turbo Balancing High Speed Dynamic Balancing Machine

High-precision YYQ-200S dynamic balancing machine for 2-200kg rotors. Ideal for motors, fans, and textile machinery. Features belt drive, industrial PC control, and piezoelectric sensors to minimize vibration and extend equipment life.

Introduction

The YYQ-200S is a versatile hard-bearing dynamic balancing machine engineered to deliver exceptional stability for rotating components. By precisely identifying and correcting unbalance, this machine helps manufacturers eliminate harmful vibrations and noise, ensuring smoother operation and significantly extending the service life of motors, fans, and industrial rollers.

Key Features:

-

Advanced Control System: Equipped with a 32-bit industrial computer and a 19-inch LCD screen utilizing proprietary software for real-time data processing and clear visualization of unbalance amount and phase.

-

Belt Drive Mechanism: Ensures high precision measurement without affecting the workpiece surface quality; ideal for rotors requiring high balancing accuracy.

-

Robust Construction: Features a 1200mm lathe bed made of HT250 cast iron and QT450 integral swing frames, providing superior rigidity and vibration damping.

-

High Sensitivity: Utilizes piezoelectric sensors and an elastic beam structure to detect even minute unbalance variations (≤0.5 gmm/kg).

-

Variable Speed Control: Integrated 1.5 kW motor with a frequency converter allows for adjustable speeds between 200-1500 r/min to suit various workpiece types.

For universal joint balancing machines of the same specifications, please refer to: YYW-200S Dynamic Universal Joint Shaft Balancing Machine.

parameter

| Item | Specification |

| Workpiece Mass (kg) | 2 - 200 |

| Max Workpiece Diameter (mm) | φ1000 |

| Max Driving Belt Diameter (mm) | φ300 |

| Max Distance Between Pedestals (mm) | 1000 |

| Lathe Bed Length (mm) | 1200 |

| Journal Diameter Scope (mm) | φ10 - 90 |

| Min Achievable Residual Unbalance | ≤0.5 gmm/kg |

| Unbalance Reduction Ratio | ≥90% |

| Rotating Speed (r/min) | 200 - 1500 |

| Motor Power (kw) | 1.5 |

*Test data from Beacon laboratory

Related products

Language

Language