Beacon Machine Manufacturing Co.,ltd

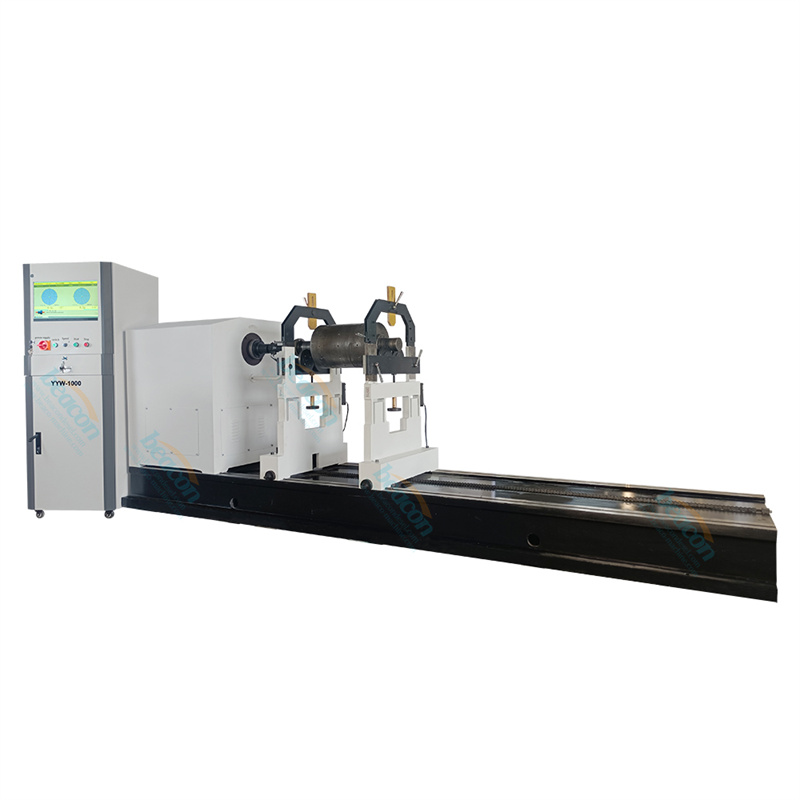

YYW-K5s Horizontal Motor Crankshaft Big Rotor Universal Joint Drive Dynamic Balancing Machine turbocharger balancing

YYW-K5s Horizontal Motor Crankshaft Big Rotor Universal Joint Drive Dynamic Balancing Machine turbocharger balancing

Introduction

parameter

2)Max diameter of work-piece universal joint driven(mm): φ2400

3)Distance between the two bearing frame:(mm) 340-3100

4)Max distance from universal joint interface to right swing frame center(mm) 3100

5)Journal diameter scope of work-piece(mm): φ20-150(standard bearing roller frame)

6)Min achievable residual unbalance amount(gmm/kg): ≤1

7)Unbalance reduction ratio(%): ≥90

8) Rotating speed(r/min): 250/435/708/1164 Step less speed regulation

9) Motor power(kw): 15

10) Drive mode: universal spindle coupling

11) Work environment: temperature: -5---45℃; humidity: 0-85%

*Test data from Beacon laboratory

Main technical index

Way of driving: universal joint driven, 15 kw motor and LINGONG four speed gearbox

Measuring system: independent developed dynamic balancing machine special measuring software.

Device configuration:

1) lathe bed dimension: 4300mm lathe bed, there are two T type grooves on lathe bed for move and fasten swing frame.

2)There are two sets standard bearing frame on lathe bed

The swing frame made by QT450 cast iron, integral structure, roller bearing by cantilever, with lockable and adjustable clamp safety frame, there is piezoelectric sensor assembly behind elastic beam, used to measuring the shake of swing frame.

3)universal joint driven part:

One head stock

One set 15kw motor and LINGONG four speed gearbox

One set universal spindle coupling with graduated disc

One set special universal joint, with safety cover

One set reference signal sensor

4)strong current system include:

Operation control panel ahead control cabinet installed power switch, start stop knob, inside vertical industry cabinet installed strong current controlling circuit board, air switch, all above low-voltage components adopt domestic famous brands. Use Shenzhen IVNT frequency converter to realized step less speed regulation.

5)measuring system include:

One set 32 bits industrial control computer;

One set 19 inches flat panel LCD monitor;

One piece LENOVO anti-interference keyboard, one piece mouse;

One set high-end electronic control cabinet;

A set of foundation bolt, wedge iron for leveling, and tools with the machine;

A set of balancing machine software and technical manual.

Our factory

Our Service

Related products