Beacon Machine Manufacturing Co.,ltd

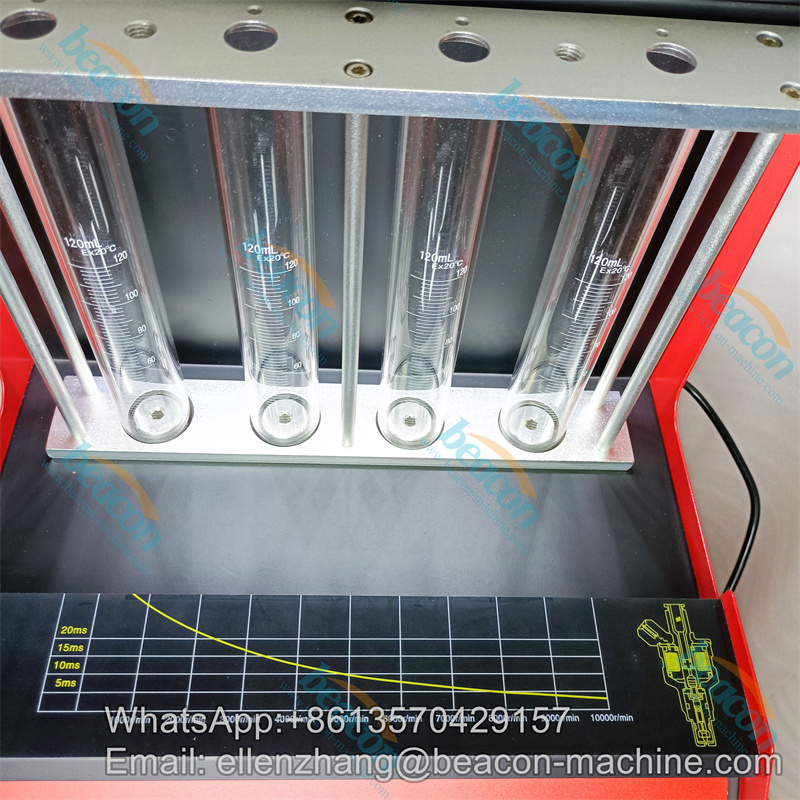

BC-4H gasoline Fuel Injector analyzer & cleaner with 4 cylinder

The BC-4H is a specialized cleaning machine for gasoline injectors, ensuring optimal fuel atomization and engine performance through thorough and efficient cleaning processes.

Introduction

BC-4H gasoline Fuel Injector analyzer & cleaner with 4 cylinder

Main Functions:

- Reverse Flushing, Flush-Back Cleaning, Ultrasonic Flushing, and Non-Affiliation Flushing: Capable of performing reverse flushing, flush-back cleaning, ultrasonic flushing, and non-affiliation flushing on one or more fuel injectors.

- Automatic Simulation: Automatically simulates the overall process under various pulse widths and engine speeds. The operation status of the fuel injectors can also be observed during acceleration and deceleration.

- Manual Settings: Allows manual setting of time, pulse width, and rotation speed of the fuel injector, and enables observation of performance under varied parameters. Provides ease and convenience of operation.

- Cycle and Quality Determination: Determines the shortest on-off cycle and the quality of the injector.

- Oil Circuit Testing and Non-Affiliation Flushing: Capable of oil circuit testing and non-affiliation flushing of the engine.

- Ultrasonic Cleaning: Performs ultrasonic cleaning for single or multiple injectors, thoroughly removing carbon deposits from the injectors.

- Uniformity Test: Tests the uniformity of the spray nozzle.

- Atomization Observation: Using background light, allows comprehensive and careful observation of nozzle jet atomization.

- Leak Test: Detects injector sealing and dripping under high pressure.

- Fuel Injection Quantity Detection: Detects the quantity of fuel injection under certain operating conditions (such as the same time and timer).

- Automatic Cleaning Detection: Simulates actual nozzle tests under various conditions and performs cleaning detection under specific operating conditions.

parameter

| Technical Parameter | Specification |

|---|---|

| Dimension | 580mm × 490mm × 730mm |

| Weight | 45kgs |

| Voltage | AC220V/110V±10%, 50/60Hz |

| Operation Temperature | -10°C to 40°C |

| Tank Capacity | 4L |

| Test Tube Capacity | 125CC |

| Ultrasonic Frequency | 28KHZ±0.5 KHZ |

| Rotation Speed | 0~15000r/min |

| Step (Rotation Speed) | 100r/min |

| Time Counting Range | 0~9900 sec |

| Step (Time Counting) | 50 sec (adjustable) |

| Oil Pump Pressure | 1.8kg/cm² to 10kg/cm² |

| Fuel Flow | 4.5 L/min |

*Test data from Beacon laboratory

product video

Related products