Beacon Machine Manufacturing Co.,ltd

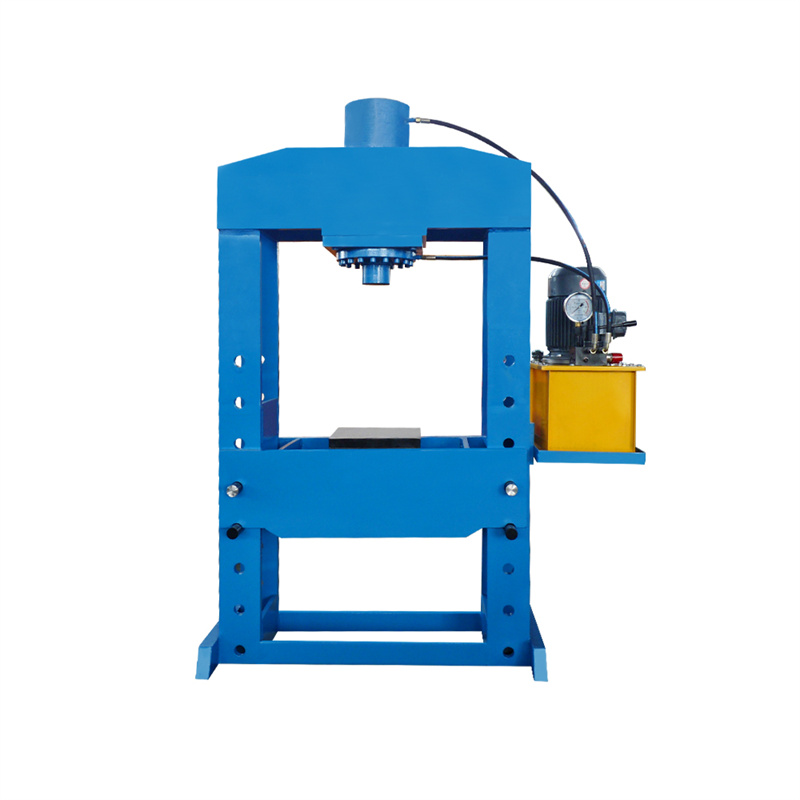

BT Electric Hydraulic Press Series 150~1500KG

Enhance your production efficiency with our state-of-the-art hydraulic press, designed for precise and powerful pressing, molding, and forming applications

Introduction

BT Electric Hydraulic Press Series 150~1500KG

parameter

- Manual adjustment using external force like a forklift.

- Main oil jar mode using linking poles.

- Manual rocking using a handle and gear transmission.

- Subsidiary oil jar mode for pillar movement.

- Manual revolving switch valve.

- Key switch.

- Remote control switch.

- Treadle switch.

- Electrical wires must be high quality and properly sealed.

- Regular hydraulic oil changes every 3000 hours (N20-30 in winter, N46 in summer).

*Test data from Beacon laboratory

product video

Related products