Beacon Machine Manufacturing Co.,ltd

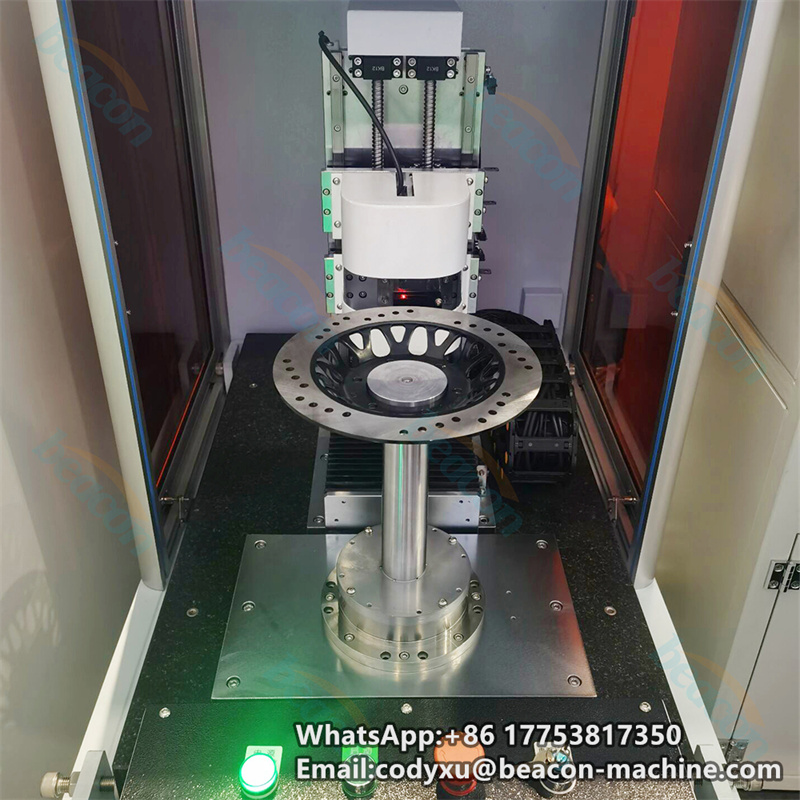

Beacon Auto Repair BD101 Brake Disc Laser Semi-automatic Testing Machine

Beacon Auto Repair BD101 Brake Disc Laser Semi-automatic Testing Machine adjust the position of the laser sensor and recalibrate it.

Introduction

Main configurations

1. Instrument used: Sampling high-precision laser sensor, measurement range ± 3.7mm, linear

Error: ± 0.015% F.S (actual testing accuracy reaches ± 0.94um) configured with Taiwan Advantech industrial control computer, brand I/O board, and motion control board.

2. Automatic removal of brake disc faces and grooves

3. Configure 1 set of 2-level measuring blocks for calibrating laser sensors. When changing the measurement specifications, it is necessary to adjust the position of the laser sensor and recalibrate it.

4. Mechanical part

The spindle adopts a high-precision air floating spindle, with an end face runout of less than 0.001mm. The horizontal axis is sampled by Japan THK high-precision linear guide rail

The two axis motion is driven by a servo motor.

Measurement functions

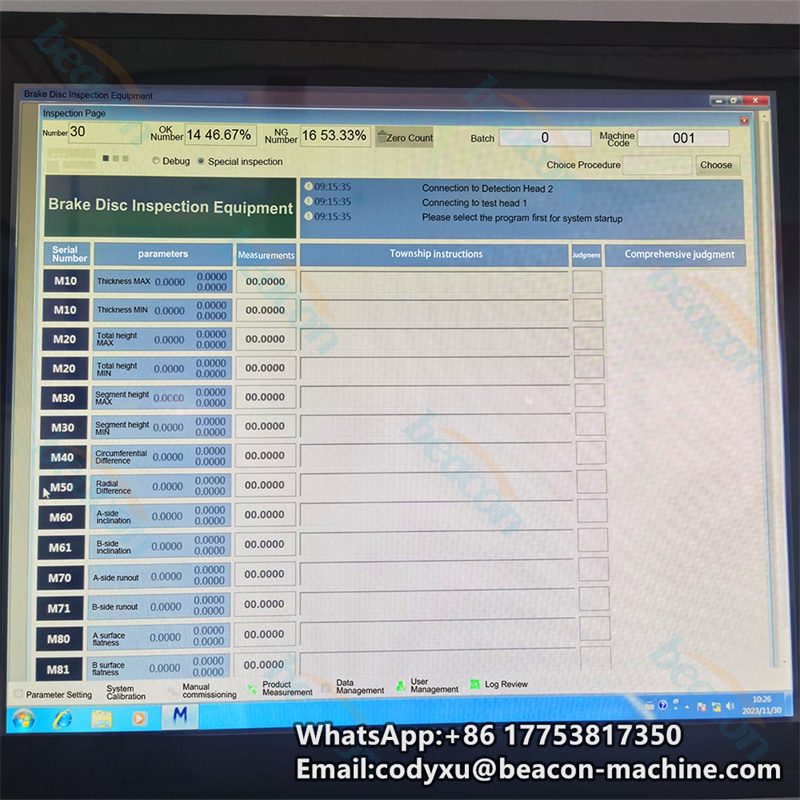

1. Measuring a two-week rhythm of less than 10 seconds per piece

2. Repetitive measurement accuracy: The thickness dimension of the disk surface is ± 0.0015mm,

Circumferential thickness difference ± 0.0015mm, other geometric tolerances ± 0.003mm

3. The device software has an automatic saving function and can automatically calculate the defect rate and composite ratio

Grid rate and similar data.

4. Judgment basis: The equipment is calibrated with standard parts before use, and the accuracy of the process is compared with manual testing.

5. Equipment size (length * width * height) is approximately 0.8M * 1M * 2.1M.

1. Instrument used: Sampling high-precision laser sensor, measurement range ± 3.7mm, linear

Error: ± 0.015% F.S (actual testing accuracy reaches ± 0.94um) configured with Taiwan Advantech industrial control computer, brand I/O board, and motion control board.

2. Automatic removal of brake disc faces and grooves

3. Configure 1 set of 2-level measuring blocks for calibrating laser sensors. When changing the measurement specifications, it is necessary to adjust the position of the laser sensor and recalibrate it.

4. Mechanical part

The spindle adopts a high-precision air floating spindle, with an end face runout of less than 0.001mm. The horizontal axis is sampled by Japan THK high-precision linear guide rail

The two axis motion is driven by a servo motor.

Measurement functions

1. Measuring a two-week rhythm of less than 10 seconds per piece

2. Repetitive measurement accuracy: The thickness dimension of the disk surface is ± 0.0015mm,

Circumferential thickness difference ± 0.0015mm, other geometric tolerances ± 0.003mm

3. The device software has an automatic saving function and can automatically calculate the defect rate and composite ratio

Grid rate and similar data.

4. Judgment basis: The equipment is calibrated with standard parts before use, and the accuracy of the process is compared with manual testing.

5. Equipment size (length * width * height) is approximately 0.8M * 1M * 2.1M.

parameter

Product Name:BD101 Brake Disc Laser Semi-automatic Testing Machine

power supply:AC220V±10%

temperature:5℃-40℃

Gas source:0.5~0.7Mpa

Single package size:30X30X30 cm

Single gross weight:30.000 kg

*Test data from Beacon laboratory

power supply:AC220V±10%

temperature:5℃-40℃

Gas source:0.5~0.7Mpa

Single package size:30X30X30 cm

Single gross weight:30.000 kg

*Test data from Beacon laboratory

Related products