Beacon Machine Manufacturing Co.,ltd

Beacon YYQ-1A Small Armature Balancing Machine Rotor Balancing Machine Turbocharger Test Bench Portable Dynamic

Beacon YYQ-1A Small Armature Balancing Machine Rotor Balancing Machine Turbocharger Test Bench Portable Dynamic

Introduction

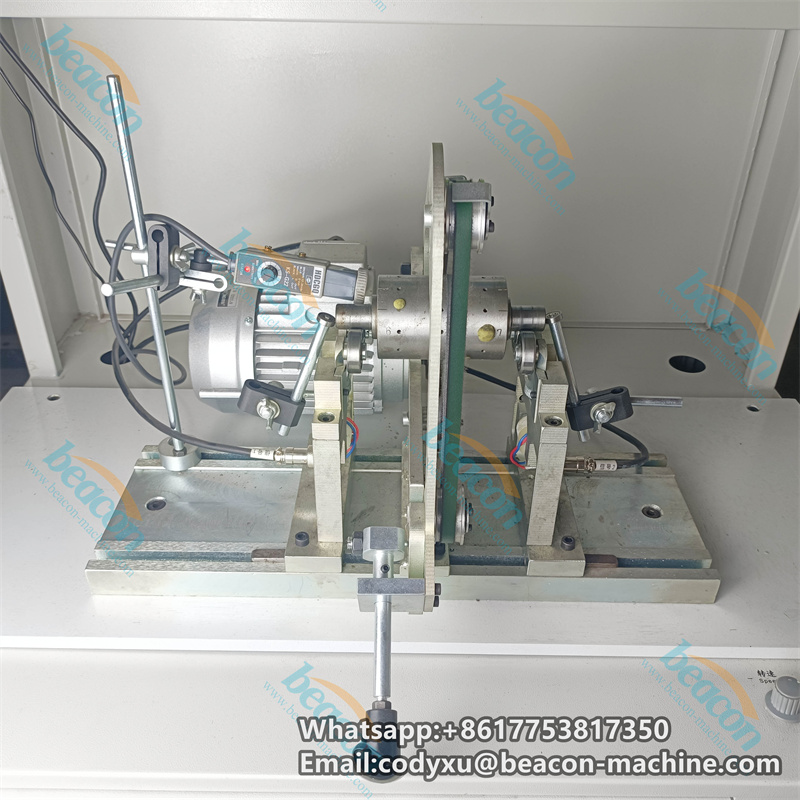

YYQ-1A Rotor Core Balancing Machine

The series of hard support ring belt driven double-sided horizontal dynamic balancing machines produced by our company are produced in strict accordance with GB/T 4 2 0 1-2006, and the models range from tens of grams to 10,000 kilograms. The product adopts roller support, ring belt dragging, and the overall casting stability of the bed is good. At the same time, it adopts vector frequency conversion stepless speed regulation technology. It is suitable for the balance test of regular cylindrical workpieces with relatively smooth surface. It is also suitable for other tools with suitable fixtures. Workpiece measurement has been widely used in electric motors, fans, diesel engines, auto parts and other industries. It can perform balance measurement on one-sided, two-sided, and multiple calibration surfaces. It is suitable for shafts, disks and rotors with outstretched centers of gravity. Industrial control computer for data processing, 19-inch LCD screen displays: imbalance, phase angle and real-time speed. The software adopts GB-2000 general-purpose microcomputer balance measurement system, runs under Windows, fully automatic program-controlled amplification module, simple operation and convenient use. Vector graphics, waveform and imbalance are displayed at the same time. It has the characteristics of high efficiency, accurate precision, intuitive display, reliable quality and convenient maintenance. Arbitrary input of real parameters, arbitrary calibration, arbitrary angle fixture compensation, self-check, qualified quantity prompt, remaining unbalance g (gram) and unbalance torque g.cm (gram*cm), g.mm (gram*mm) can be realized Multiple display modes, automatic storage of measurement results, operation of all English menu structures, and automatic prompts.

The series of hard support ring belt driven double-sided horizontal dynamic balancing machines produced by our company are produced in strict accordance with GB/T 4 2 0 1-2006, and the models range from tens of grams to 10,000 kilograms. The product adopts roller support, ring belt dragging, and the overall casting stability of the bed is good. At the same time, it adopts vector frequency conversion stepless speed regulation technology. It is suitable for the balance test of regular cylindrical workpieces with relatively smooth surface. It is also suitable for other tools with suitable fixtures. Workpiece measurement has been widely used in electric motors, fans, diesel engines, auto parts and other industries. It can perform balance measurement on one-sided, two-sided, and multiple calibration surfaces. It is suitable for shafts, disks and rotors with outstretched centers of gravity. Industrial control computer for data processing, 19-inch LCD screen displays: imbalance, phase angle and real-time speed. The software adopts GB-2000 general-purpose microcomputer balance measurement system, runs under Windows, fully automatic program-controlled amplification module, simple operation and convenient use. Vector graphics, waveform and imbalance are displayed at the same time. It has the characteristics of high efficiency, accurate precision, intuitive display, reliable quality and convenient maintenance. Arbitrary input of real parameters, arbitrary calibration, arbitrary angle fixture compensation, self-check, qualified quantity prompt, remaining unbalance g (gram) and unbalance torque g.cm (gram*cm), g.mm (gram*mm) can be realized Multiple display modes, automatic storage of measurement results, operation of all English menu structures, and automatic prompts.

parameter

Device model: YYQ-1.0A

Workpiece mass range kg:0.05-1

Maximum diameter of workpiece mm:260

Distance between two supports mm:30-260

Diameter range of ring belt dragging place mm:15-80

Support shaft diameter mm:4-17

Balance speed r/min:400-1500 when the diameter of the drag is 50mm

Minimum residual unbalance≤0.5gmm/kg

Unbalance reduction rate%:≥90%

Measuring time (not including start and stop time)≤10S (related to measuring speed and setting period)

Motor Power:90W

Speed mode Frequency

Transfer method Band

Maximum power consumption of the device:<1kw

Equipment powerAC: 220V,50HZ

Equipment size:800*650*1020mm

*Test data from Beacon laboratory

Workpiece mass range kg:0.05-1

Maximum diameter of workpiece mm:260

Distance between two supports mm:30-260

Diameter range of ring belt dragging place mm:15-80

Support shaft diameter mm:4-17

Balance speed r/min:400-1500 when the diameter of the drag is 50mm

Minimum residual unbalance≤0.5gmm/kg

Unbalance reduction rate%:≥90%

Measuring time (not including start and stop time)≤10S (related to measuring speed and setting period)

Motor Power:90W

Speed mode Frequency

Transfer method Band

Maximum power consumption of the device:<1kw

Equipment powerAC: 220V,50HZ

Equipment size:800*650*1020mm

*Test data from Beacon laboratory

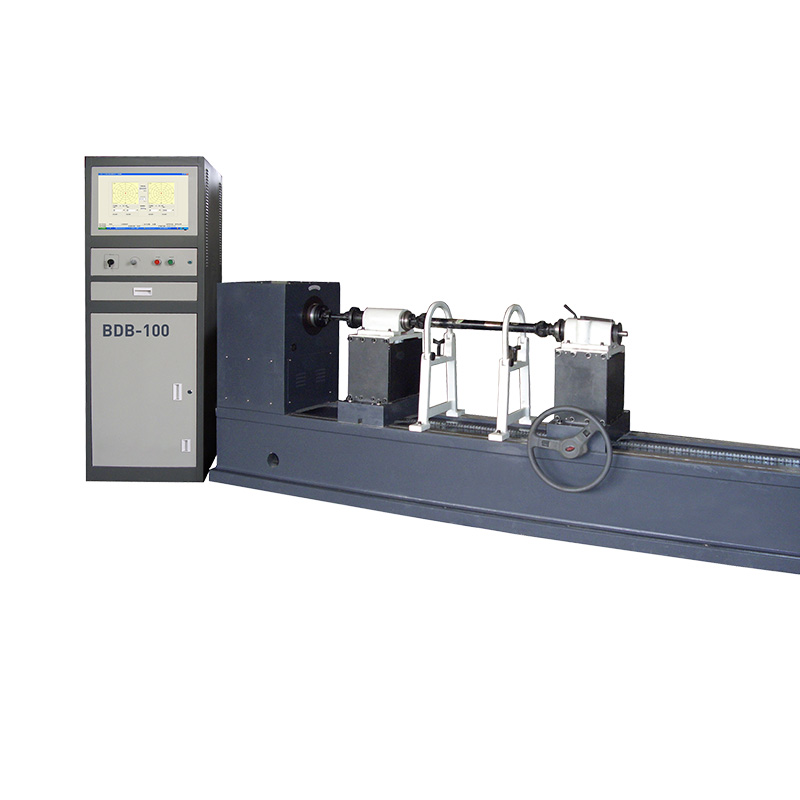

Related products