Beacon Machine Manufacturing Co.,ltd

Rotor Vibration Instrument YYQ-50A Crankshaft Balancer Grinding Crank Shaft Balancing Machine

Rotor Vibration Instrument YYQ-50A Crankshaft Balancer Grinding Crank Shaft Balancing Machine

Introduction

INTRODUCTION

Industrial control computer 19 "LCD color screens

WidowsChinese and English system double choice

With GB-2000 general microcomputer balance measuring system

Automatic program-controlled amplifier module

Any workpiece scaling function, arbitrary Angle clamp compensating and workpiece information storage

Qualified quantity showed that adjustment function measurement cycle

Signal amplifier amplification and manual adjustment, signal self-check, automatic diagnosis

Vector graphics, waveform and out of balance, shows at the same time

Surplus balabcing g and unbalanced torque, the g cm, g mm can choose to display

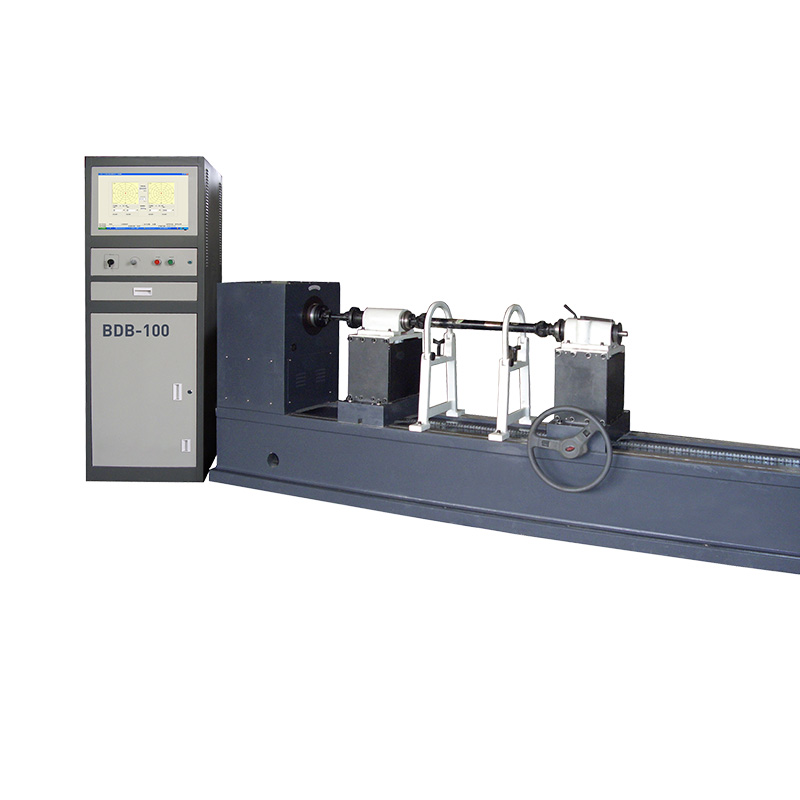

This series is hard supporting horizontal dynamic balance machine, with roller bearing, the circle take drag, regular for double speed motor drive, "A" type for frequency conversion motor speed and frequency converter, the industrial control computer for data processing, color screen real-time display don’t balance phase Angle and value, real-time speed, lathe bed all use whole casting, the stability is good.Widely used in electric motors, blower, diesel engine, auto parts, etc, can be in the single side, double side and multiple correction plane balance measurement, suitable for axle, dish out and center of gravity of the rotor. Have high efficiency, precision accurate, show intuitional, reliable quality, easy maintenance, the characteristics of software with ordinary workpiece and standard rotor two calibration function, overcoming the other hard supporting balance machine measurement system to users to calibration equipment of the defect, and a variety of measurement method and function to choose, can realize the input parameters, preview, the experiment, the results storage, print, operating all adopt the localization menu structure, the man-machine dialogue, automatic hints.

Industrial control computer 19 "LCD color screens

WidowsChinese and English system double choice

With GB-2000 general microcomputer balance measuring system

Automatic program-controlled amplifier module

Any workpiece scaling function, arbitrary Angle clamp compensating and workpiece information storage

Qualified quantity showed that adjustment function measurement cycle

Signal amplifier amplification and manual adjustment, signal self-check, automatic diagnosis

Vector graphics, waveform and out of balance, shows at the same time

Surplus balabcing g and unbalanced torque, the g cm, g mm can choose to display

This series is hard supporting horizontal dynamic balance machine, with roller bearing, the circle take drag, regular for double speed motor drive, "A" type for frequency conversion motor speed and frequency converter, the industrial control computer for data processing, color screen real-time display don’t balance phase Angle and value, real-time speed, lathe bed all use whole casting, the stability is good.Widely used in electric motors, blower, diesel engine, auto parts, etc, can be in the single side, double side and multiple correction plane balance measurement, suitable for axle, dish out and center of gravity of the rotor. Have high efficiency, precision accurate, show intuitional, reliable quality, easy maintenance, the characteristics of software with ordinary workpiece and standard rotor two calibration function, overcoming the other hard supporting balance machine measurement system to users to calibration equipment of the defect, and a variety of measurement method and function to choose, can realize the input parameters, preview, the experiment, the results storage, print, operating all adopt the localization menu structure, the man-machine dialogue, automatic hints.

parameter

The measuring time:10s (measurement cycle can be arbitrary set).

Software version:Windows XP

display mode:19 inch LCD

power supply:The power of three-phase four-wire type AC 380V, 50/60HZ

Working:continuously

Work piece quality range (Kg):50

Beam supporting interval distance (mm):60-700

Trunnion range (mm):Φ 5-70

Work piece diameter (mm):600

Balance speed (r/min):300-2500 variable frequency speed regulation

Motor power (KW):0.75

Unbalance reduction ratio%:≤90

Minimum can reach surplus balancing:≤0.5g・mm/kg

*Test data from Beacon laboratory

Software version:Windows XP

display mode:19 inch LCD

power supply:The power of three-phase four-wire type AC 380V, 50/60HZ

Working:continuously

Work piece quality range (Kg):50

Beam supporting interval distance (mm):60-700

Trunnion range (mm):Φ 5-70

Work piece diameter (mm):600

Balance speed (r/min):300-2500 variable frequency speed regulation

Motor power (KW):0.75

Unbalance reduction ratio%:≤90

Minimum can reach surplus balancing:≤0.5g・mm/kg

*Test data from Beacon laboratory

Related products