Beacon Machine Manufacturing Co.,ltd

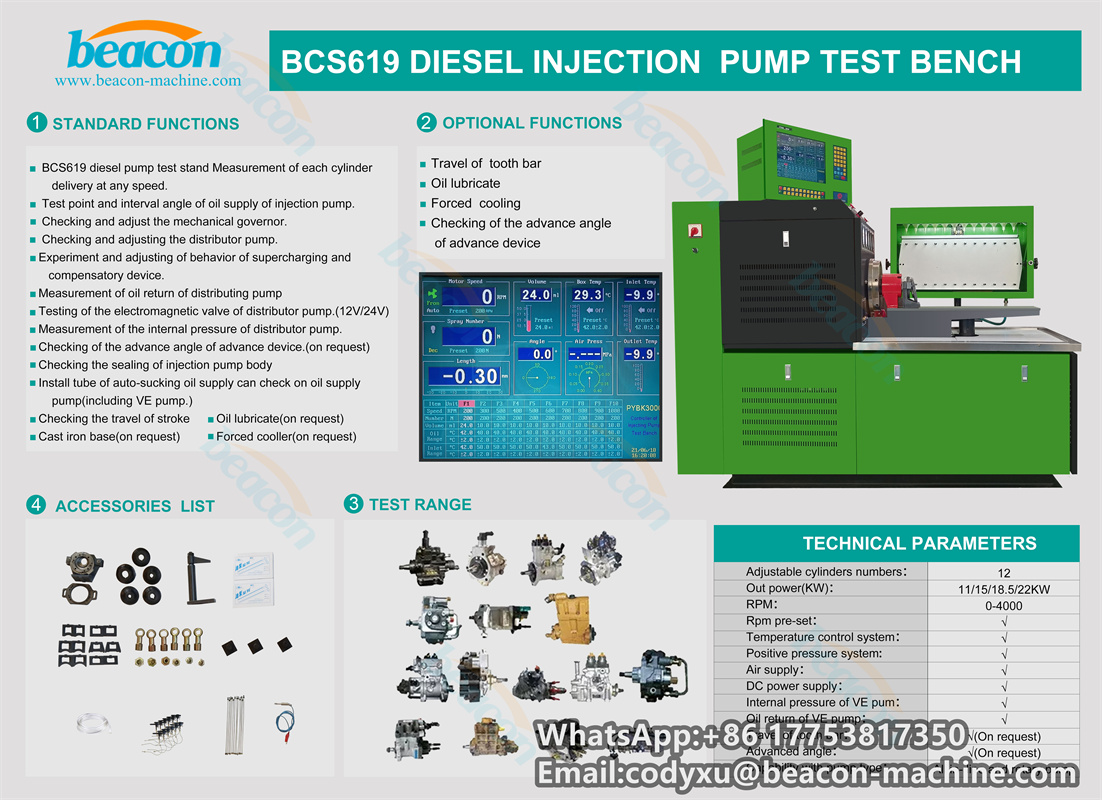

Beacon BCS619 Auto Service Diesel Fuel Injector Mechanical Pump Test Bench Bank Injection Pumps Repair Equipment

Beacon BCS619 Auto Service Diesel Fuel Injector Mechanical Pump Test Bench Bank Injection Pumps Repair Equipment Suitable for auto repair industry

Introduction

Beacon BCS619 Auto Service Diesel Fuel Injector Mechanical Pump Test Bench Bank Injection Pumps Repair Equipment

Introduction

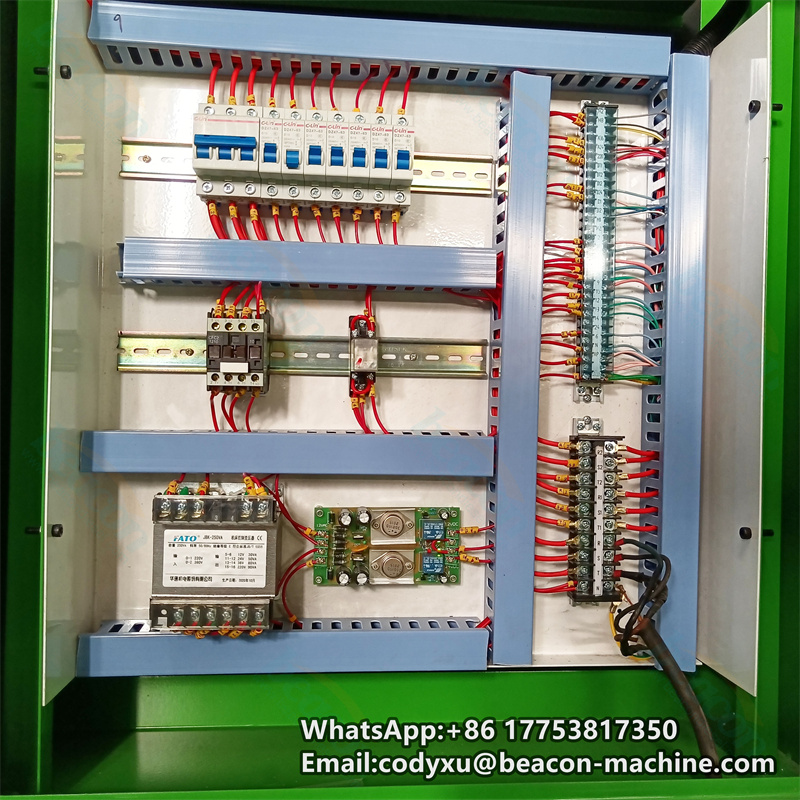

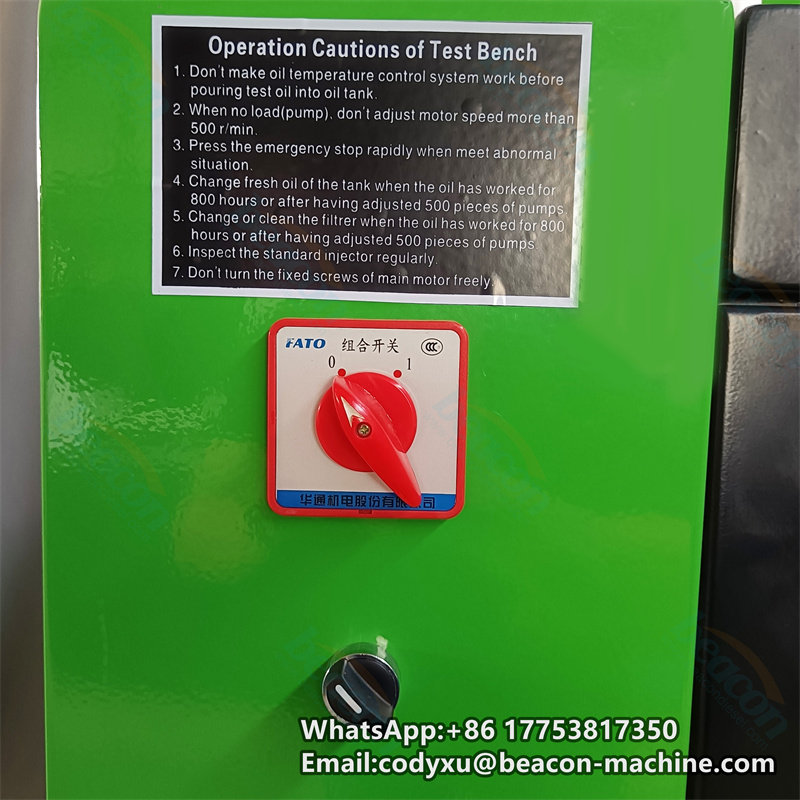

BCS619 is a kind of fuel injection pump test bench adopt industrial pc with color CRT, It's the newly researched production for the direction of high power and safety to the environment. It has human-machine interface, digital controlling of rpm, temperature, pressure, diesel fuel pump technical parameter and so on, and in pace with print. It easy and quick operates ,it's really human-machine dialog. This series test bench adopt high quality frequency conversing device and cast iron base supper size bed, and its distinguishing features are hi-stable character, hi-reliability, ultra-low-noise, perfect auto-protecting function and so on, It is advanced products.

Main function

1. BCS619 diesel pump test stand Measurement of each cylinder delivery at any speed.

2. Test point and interval angle of oil supply of injection pump.

3. Checking and adjust the mechanical governor.

4. Checking and adjusting the distributor pump.

5. .Experiment and adjusting of behavior of supercharging and compensatory device.

6. Measurement of oil return of distributing pump

7. Testing of the electromagnetic valve of distributor pump.(12V/24V)

8. Measurement of the internal pressure of distributor pump.

9. Checking of the advance angle of advance device.(on request)

10. Checking the sealing of injection pump body

11. Install tube of auto-sucking oil supply can check on oil supply pump(including VE pump.)

12. Checking the travel of stroke

13.oil lubricate(on request)

14.Cast iron base(on request)

15. Forced cooller(on request)

parameter

2. Pressure of feeding test oil:

Low pressure: 0~0.4Mpa.

High pressure: 0~4Mpa.

3. Feeding capacity of test oil: ≥10 L/min.

4. Stabilization temperature of test oil by automatic: 40±2℃.

5: Heater: 1Kw/380V.

*Test data from Beacon laboratory

product video

Related products