Beacon Machine Manufacturing Co.,ltd

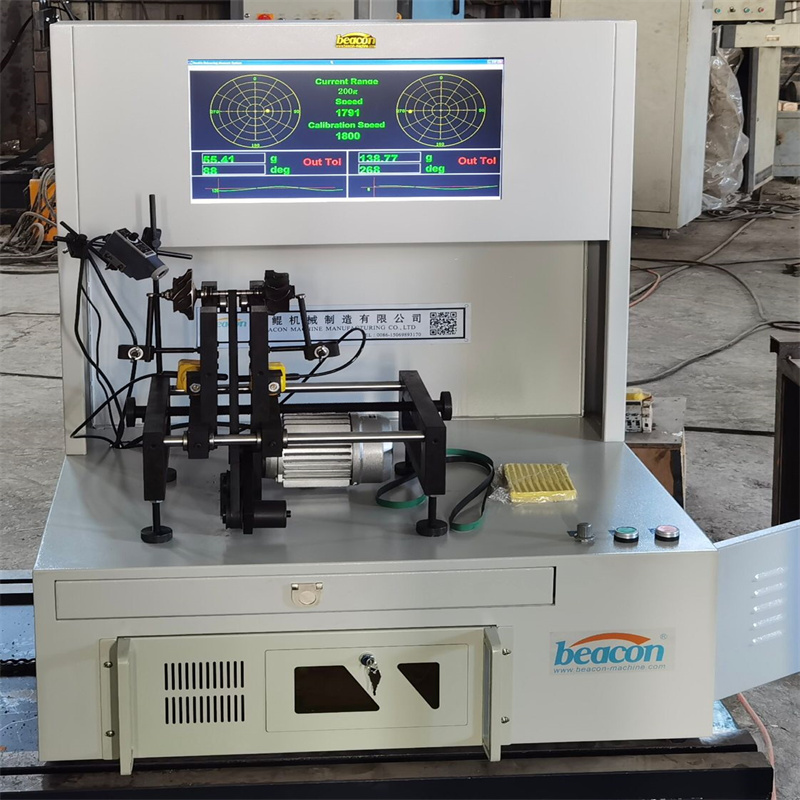

Cardan Shaft Balancing Machine YYW-K10S Turbine Drive Shaft Dynamic Engine Balancing Machine

Cardan Shaft Balancing Machine YYW-K10S Turbine Drive Shaft Dynamic Engine Balancing Machine

Introduction

1. Features:

General hard bearing dynamic balancing machine strictly according to GB/T 4201-2006 to produce, using roller bearing, universal joint driven, screen display structure, industrial control computer processing the data. 19 inches LCD screen display unbalance amount, phase angle and real-time rotating speed. It is widely used in paper making machine, textile machine, agriculture machine, electric motor, blower fan, etc, can measuring balance on single, double, multifaceted interface, suited for large axle, plate, center of gravity overhung rotor.

2. Main technical index

Way of driving: universal joint driven, 37 kw motor and four speed gearbox

For convenient to place and adjust large work-piece rotor, gearbox can fine tune about 15cm on head stock, and whole head stock can free move on lathe bed, in case of breaking universal joint when installing, and realized fast connecting.

Measuring system: independent developed dynamic balancing machine special measuring software.

General hard bearing dynamic balancing machine strictly according to GB/T 4201-2006 to produce, using roller bearing, universal joint driven, screen display structure, industrial control computer processing the data. 19 inches LCD screen display unbalance amount, phase angle and real-time rotating speed. It is widely used in paper making machine, textile machine, agriculture machine, electric motor, blower fan, etc, can measuring balance on single, double, multifaceted interface, suited for large axle, plate, center of gravity overhung rotor.

2. Main technical index

Way of driving: universal joint driven, 37 kw motor and four speed gearbox

For convenient to place and adjust large work-piece rotor, gearbox can fine tune about 15cm on head stock, and whole head stock can free move on lathe bed, in case of breaking universal joint when installing, and realized fast connecting.

Measuring system: independent developed dynamic balancing machine special measuring software.

parameter

1)weight of work-piece universal joint driven(kg): 500-10000

2)Max diameter of work-piece universal joint driven(mm): φ2400(separated lathe bed φ3200)

3)Length of lathe bed (mm): 3100*2

4)Journal diameter scope of work-piece(mm): φ40-200, φ180-360(2 sets rotor)

5)Min achievable residual unbalance amount(gmm/kg): ≤1

6)Unbalance reduction ratio(%): ≥90

7) Rotating speed(r/min): 270/476/757/1164 Step less speed regulation

8) Motor power(kw): 37

9) Drive mode: universal spindle coupling+four speed gearbox

10) Work environment:

temperature: -5---45℃;

humidity: 0-85%

*Test data from Beacon laboratory

2)Max diameter of work-piece universal joint driven(mm): φ2400(separated lathe bed φ3200)

3)Length of lathe bed (mm): 3100*2

4)Journal diameter scope of work-piece(mm): φ40-200, φ180-360(2 sets rotor)

5)Min achievable residual unbalance amount(gmm/kg): ≤1

6)Unbalance reduction ratio(%): ≥90

7) Rotating speed(r/min): 270/476/757/1164 Step less speed regulation

8) Motor power(kw): 37

9) Drive mode: universal spindle coupling+four speed gearbox

10) Work environment:

temperature: -5---45℃;

humidity: 0-85%

*Test data from Beacon laboratory

Related products